| Aluminum Core SWA Armor Power Cable | ||

| Voltage: | 0.6kV-1kV | |

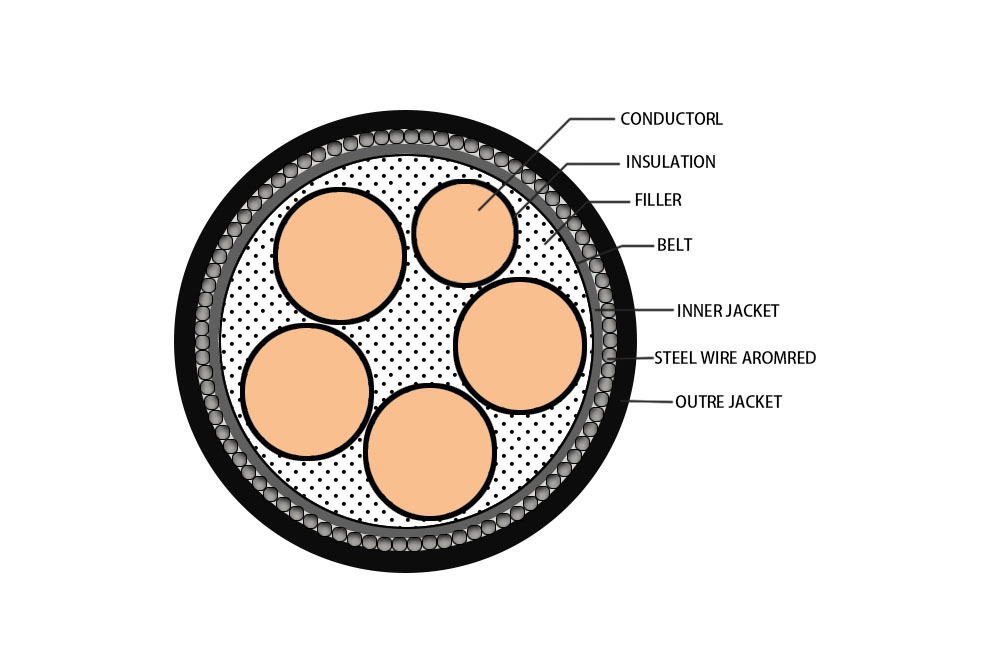

| Structure: | Conductor | Aluminum |

| Insulation | XLPE | |

| Armour | STEEL WIRE | |

| Jacket | PVC | |

This product is suitable for transmitting electric energy in power lines with AC 50Hz and rated voltage 0.6/1kV (system maximum voltage 1.2kV)

Fixed laying in metallurgy, electric power, construction and other industries indoors, cable trenches, pipelines, direct burial and other places that do not need to withstand mechanical external force.

The raw materials for product production are widely sourced and cheap, and are easy to process and manufacture.

The product is insulated with cross-linked polyethylene. Compared with PVC insulated cables, it has better insulation performance and can withstand extremely high working temperatures, up to 90 degrees.

The product is armored with steel wire and can withstand greater mechanical pressure.

GB/T 12706.1-2020 Extruded insulated power cables and accessories with rated voltage 1kV (Um=1.2kV) to 35kV (Um=40.5kV) Part 1: Rated voltage 1kV (Um=1.2kV) and 3kV (Um=3.6kV ) )cable

The rated voltage is 0.6/1kV, and the maximum voltage of the AC system should not exceed 1.2kV.

The maximum allowable long-term operating temperature of the cable conductor is 90°C; In the case of short circuit, the maximum temperature of the cable conductor shall not exceed 250 ° C and the duration shall not exceed 5s.

The minimum ambient temperature for cable operation is -15℃.

When installing and laying, the temperature should not be lower than 0℃.

The bending radius of single-core cables should be no less than 20 times the outer diameter of the cable, and the bending radius of multi-core cables should be no less than 15 times the outer diameter of the cable.

1.Color identification When multi-core cables are marked with different colors, they must comply with the following regulations: 2-core cable: red, blue; 3-core cable: yellow, green, red; 4-core cable: yellow, green, red, blue; 5-core cable Cable: yellow, green, red, blue, black (or determined by negotiation between the supplier and the buyer). The colors red, yellow and green are used for the main wire core. Blue is used for the neutral core. In order to avoid confusion with other colors, it is recommended to use light blue.

2. Digital identification When multi-core cables use digital identification, they must comply with the following regulations: 2-core cable: 0, 1; 3-core cable: 1, 2, 3; 4-core cable: 0, 1, 2, 3; 5-core cable :0,1,2,3,4. The numbers 1, 2, and 3 are used for the main core, and 0 is used for the neutral core. In a 5-core cable, the number "4" refers to the specific purpose conductor (including the grounding conductor). When the insulated cores are marked with numbers, the insulation should be of the same color and arranged according to the numbers. Numbers should be printed on the surface of the insulated core with Arabic numerals. The color of the numbers should be the same and have obvious contrast with the insulation color and the writing should be clear; the number signs should be repeated at equal intervals along the insulated core, and two adjacent sets of number signs should be Invert each other. When the logo consists of a single number, a dash should be placed below the number. If the The logo consists of two numbers, it should be arranged up and down and a dash should be placed below the subsequent numbers. The spacing between two adjacent sets of digital logos is d. Should be no larger than 50mm.

The outer sheath of the cable is usually black, but it can also be in colors other than black according to the manufacturer or buyer's agreement to adapt to its use environment. The cable should have continuous identification of the manufacturer's name, product model and rated voltage . The manufacturer's name identification can be Duplicate identification of manufacturer or trademark. The printed logo should be scratch-resistant and not fall off, and the printed content on the surface should be clearly legible. Note: The logo on the surface of the sheath can also add other logo contents according to the habits of the user or manufacturer.

Cables weighing less than 80kg are allowed to be delivered in coils, and the delivery length of short-segment cables should not exceed 5% of the total delivery length, or cables of any length can be delivered according to mutual agreement.

Delivery length measurement error is ±0.5%

Cables in rolls or coils should be neatly wound and properly packed. The cable tray shall comply with GB/T 8137-1999. The cable ends should be securely sealed. The cable ends extending out of the disk should be covered with a protective cover. The length of the cable ends extending out of the disk should be less than 300mm. The cable package shall bear a label indicating: Manufacturer name, model, specification, rated voltage, length, quality, manufacturing date, standard number or certification mark, the correct rotation direction of the cable tray, etc.

Transportation is generally in the form of vehicles and ships, and the cable must be firmly fixed during transportation to avoid mutual collision or tipping over and causing damage to the cable or equipment. Cable tray is not allowed to lay flat. It is strictly forbidden to drop the cable tray with the cable from the height during transportation.

The finished cable should be stored in an environment where the temperature is between 0 and 40 ° C and the humidity is below 85%, so that it is not directly exposed to sunlight or rain, and it should be properly ventilated to keep the environment dry. Cables are stored and used in accordance with the above requirements and can generally be used for more than 25 years.

When ordering, the cable model, specification, length, delivery date, packing method and other necessary information should be correctly marked. For example:

Model: YJV

Specification: 3×16

Length: 1000m

Packing method: iron tray packing

Delivery date: last day valid

Mode of transport: train transport, car transport, ship transport or air transport

Place of delivery: buyer's warehouse or site or buyer's own delivery

Note: The mode of transportation and place of delivery shall be specified by the buyer.

During installation, the ambient temperature should not be lower than 0 ° C. If the ambient temperature measured by the thermometer is lower than 0 ° C, preheat the cable before preparing for installation. The bending radius during cable laying should be strictly controlled to avoid mechanical damage inside the cable.

| Rated voltage |

No,of CORES |

core ×cross secticn (MM) |

CONDUCTOR | CORE DIANETER (MM2) |

INSULATION THCKNESS (MM) |

BELT (MM) |

INNER SHEATH THCKNESS (MM) |

ARMOR (MM) |

OUTER SHEATH THCKNESS (MM) |

Reference outer diameter (MM) |

Reference weight (kg/km) |

DC RESISTANCE (Ω/KM) |

| 0.6/1KV | 2 | 2×10 | 7/1.35 | 4.05 | 0.7 | 20×0.20 | 1 | 35×1.25 | 1.8 | 20.2 | 697.5 | 3.08 |

| 2 | 2×16 | 7/1.66 | 4.98 | 0.7 | 20×0.20 | 1 | 40×1.25 | 1.8 | 22.2 | 822.4 | 1.91 | |

| 2 | 2×25 | 7/2.14 | 6.42 | 0.9 | 25×0.20 | 1 | 39×1.6 | 1.8 | 26.5 | 1222.8 | 1.2 | |

| 2 | 2×35 | 7/2.52 | 7.56 | 0.9 | 25×0.20 | 1 | 43×1.6 | 1.8 | 28.9 | 1406.8 | 0.868 | |

| 2 | 2×50 | 10/2.52 | 5.7×13.5 | 1 | 40×0.20 | 1 | 36×1.6 | 1.8 | 24.8 | 1206.1 | 0.641 | |

| 2 | 2×70 | 14/2.52 | 7.0×15.6 | 1.1 | 45×0.20 | 1 | 41×1.6 | 2 | 28.2 | 1479.8 | 0.443 | |

| 2 | 2×95 | 19/2.52 | 8.3×18.0 | 1.1 | 55×0.20 | 1.2 | 38×2.0 | 2.1 | 32.2 | 2022.2 | 0.32 | |

| 2 | 2×120 | 24/2.52 | 8.9×20.8 | 1.2 | 60×0.20 | 1.2 | 40×2.0 | 2.2 | 34 | 2269.6 | 0.253 | |

| 2 | 2×150 | 30/2.52 | 10.0×23.1 | 1.4 | 60×0.20 | 1.2 | 45×2.0 | 2.3 | 37.2 | 2656.5 | 0.206 | |

| 2 | 2×185 | 37/2.52 | 11.1×25.7 | 1.6 | 60×0.20 | 1.4 | 40×2.5 | 2.5 | 42 | 3472.6 | 0.164 | |

| 2 | 2×240 | 48/2.52 | 12.5×29.1 | 1.7 | 60×0.20 | 1.4 | 44×2.5 | 2.7 | 45.6 | 4067.6 | 0.125 | |

| 2 | 2×300 | 61/2.52 | 15.0×32.2 | 1.8 | 60×0.20 | 1.6 | 51×2.5 | 2.8 | 51.6 | 4910.9 | 0.1 | |

| 3 | 3×10 | 7/1.35 | 4.05 | 0.7 | 20×0.20 | 1 | 38×1.25 | 1.8 | 21.1 | 774.7 | 3.08 | |

| 3 | 3×16 | 7/1.66 | 4.98 | 0.7 | 20×0.20 | 1 | 43×1.25 | 1.8 | 23.3 | 917.5 | 1.91 | |

| 3 | 3×25 | 7/2.14 | 6.42 | 0.9 | 25×0.20 | 1 | 41×1.6 | 1.8 | 27.8 | 1353.9 | 1.2 | |

| 3 | 3×35 | 7/2.52 | 7.56 | 0.9 | 25×0.20 | 1 | 46×1.6 | 1.8 | 30.4 | 1584.3 | 0.868 | |

| 3 | 3×50 | 10/2.52 | 7.0×11.5 | 1 | 50×0.20 | 1 | 42×1.6 | 1.9 | 28.6 | 1531 | 0.641 | |

| 3 | 3×70 | 14/2.52 | 8.0×13.7 | 1.1 | 55×0.20 | 1.2 | 39×2.0 | 2 | 32.5 | 2114.8 | 0.443 | |

| 3 | 3×95 | 19/2.52 | 9.5×15.8 | 1.1 | 60×0.20 | 1.2 | 44×2.0 | 2.2 | 36.1 | 2553.5 | 0.32 | |

| 3 | 3×120 | 24/2.52 | 10.8×18.6 | 1.2 | 60×0.20 | 1.2 | 48×2.0 | 2.3 | 39.5 | 2959.4 | 0.253 | |

| 3 | 3×150 | 30/2.52 | 12.5×20.5 | 1.4 | 60×0.20 | 1.4 | 45×2.5 | 2.5 | 45.7 | 3990.4 | 0.206 | |

| 3 | 3×185 | 37/2.52 | 14.3×23.3 | 1.6 | 60×0.20 | 1.4 | 50×2.5 | 2.6 | 50.5 | 4642.8 | 0.164 | |

| 3 | 3×240 | 48/2.52 | 16.3×26.2 | 1.7 | 60×0.20 | 1.6 | 56×2.5 | 2.8 | 56 | 5571.6 | 0.125 | |

| 3 | 3×300 | 61/2.52 | 18.0×29.8 | 1.8 | 60×0.20 | 1.6 | 61×2.5 | 3 | 60.4 | 6492.9 | 0.1 | |

| 4 | 4×10 | 7/1.35 | 4.05 | 0.7 | 20×0.20 | 1 | 41×1.25 | 1.8 | 22.6 | 869.6 | 3.08 | |

| 4 | 4×16 | 7/1.66 | 4.98 | 0.7 | 25×0.20 | 1 | 37×1.6 | 1.8 | 25.7 | 1186.7 | 1.91 | |

| 4 | 4×25 | 7/2.14 | 6.42 | 0.9 | 25×0.20 | 1 | 45×1.6 | 1.8 | 30 | 1551.1 | 1.2 | |

| 4 | 4×35 | 7/2.52 | 7.56 | 0.9 | 25×0.20 | 1 | 50×1.6 | 1.9 | 33.1 | 1834.5 | 0.868 | |

| 4 | 4×50 | 10/2.52 | 7.5×10.5 | 1 | 55×0.20 | 1 | 46×1.6 | 2 | 30.7 | 1801.3 | 0.641 | |

| 4 | 4×70 | 14/2.52 | 9.1×12.5 | 1.1 | 60×0.20 | 1.2 | 44×2.0 | 2.2 | 36.3 | 2555.7 | 0.443 | |

| 4 | 4×95 | 19/2.52 | 11.0×13.3 | 1.1 | 60×0.20 | 1.2 | 50×2.0 | 2.3 | 40.6 | 3098.5 | 0.32 | |

| 4 | 4×120 | 24/2.52 | 12.0×17.0 | 1.2 | 60×0.20 | 1.4 | 44×2.5 | 2.5 | 45.1 | 4029.3 | 0.253 | |

| 4 | 4×150 | 30/2.52 | 13.9×19.7 | 1.4 | 60×0.20 | 1.4 | 50×2.5 | 2.6 | 50.3 | 4771 | 0.206 | |

| 4 | 4×185 | 37/2.52 | 15.2×21.2 | 1.6 | 60×0.20 | 1.4 | 55×2.5 | 2.8 | 54.5 | 5550.6 | 0.164 | |

| 4 | 4×240 | 48/2.52 | 17.3×24.3 | 1.7 | 60×0.20 | 1.6 | 61×2.5 | 3 | 60.3 | 6662.9 | 0.125 | |

| 4 | 4×300 | 61/2.52 | 19.5×27.9 | 1.8 | 60×0.20 | 1.6 | 67×2.5 | 3.2 | 66 | 7854.8 | 0.1 | |

| 5 | 5×10 | 7/1.35 | 4.05 | 0.7 | 25×0.20 | 1 | 45×1.25 | 1.8 | 24.1 | 976.9 | 3.08 | |

| 5 | 5×16 | 7/1.66 | 4.98 | 0.7 | 25×0.20 | 1 | 40×1.6 | 1.8 | 27.5 | 1327 | 1.91 | |

| 5 | 5×25 | 7/2.14 | 6.42 | 0.9 | 25×0.20 | 1 | 50×1.6 | 1.8 | 32.4 | 1777.3 | 1.2 | |

| 5 | 5×35 | 7/2.52 | 7.56 | 0.9 | 30×0.20 | 1 | 55×1.6 | 1.9 | 35.8 | 2100.8 | 0.868 | |

| 5 | 5×50 | 10/2.52 | 4.8×14.2 | 1 | 60×0.20 | 1.2 | 41×2.0 | 2.1 | 34.2 | 2343.7 | 0.641 | |

| 8.4 | 1 | |||||||||||

| 5 | 5×70 | 14/2.52 | 5.7×16.8 | 1.1 | 60×0.20 | 1.2 | 47×2.0 | 2.3 | 38.5 | 2905.4 | 0.443 | |

| 10 | 1.1 | |||||||||||

| 5 | 5×95 | 19/2.52 | 6.7×19.6 | 1.1 | 60×0.20 | 1.4 | 43×2.5 | 2.4 | 43.7 | 3933 | 0.32 | |

| 11.6 | 1.1 | |||||||||||

| 5 | 5×120 | 24/2.52 | 7.9×21.9 | 1.2 | 60×0.20 | 1.4 | 48×2.5 | 2.6 | 48.4 | 4643.7 | 0.253 | |

| 13 | 1.2 | |||||||||||

| 5 | 5×150 | 30/2.52 | 8.5×24.6 | 1.4 | 60×0.20 | 1.4 | 52×2.5 | 2.8 | 52.6 | 5403.4 | 0.206 | |

| 14.6 | 1.4 | |||||||||||

| 5 | 5×185 | 37/2.52 | 9.4×27.2 | 1.6 | 60×0.20 | 1.6 | 58×2.5 | 3 | 57.8 | 6402.8 | 0.164 | |

| 16.2 | 1.6 | |||||||||||

| 5 | 5×240 | 48/2.52 | 10.8×31.0 | 1.7 | 60×0.20 | 1.6 | 65×2.5 | 3.2 | 63.8 | 7693.4 | 0.125 | |

| 18.5 | 1.7 | |||||||||||

| 5 | 5×300 | 61/2.52 | 12.2×34.4 | 1.8 | 60×0.20 | 1.8 | 57×3.15 | 3.4 | 71.3 | 9959 | 0.1 | |

| 20.6 | 1.8 | |||||||||||

| 4 | 3×16+1×10 | 7/1.66 | 4.98 | 0.7 | 25×0.20 | 1 | 45×1.25 | 1.8 | 24.4 | 966.4 | 1.91 | |

| 7/1.35 | 4.05 | 0.7 | ||||||||||

| 5 | 3×16+2×10 | 7/1.66 | 4.98 | 0.7 | 25×0.20 | 1 | 38×1.6 | 1.8 | 26.4 | 1183.3 | 1.91 | |

| 7/1.35 | 4.05 | 0.7 | ||||||||||

| 7/1.35 | 4.05 | 0.7 | ||||||||||

| 4 | 3×25+1×16 | 7/2.14 | 6.42 | 0.9 | 25×0.20 | 1 | 43×1.6 | 1.8 | 28.9 | 1416.5 | 1.2 | |

| 7/1.66 | 4.98 | 0.7 | ||||||||||

| 5 | 3×25+2×16 | 7/2.14 | 6.42 | 0.9 | 25×0.20 | 1 | 46×1.6 | 1.8 | 30.4 | 1510.1 | 1.2 | |

| 7/1.66 | 4.98 | 0.7 | ||||||||||

| 7/1.66 | 4.98 | 0.7 | ||||||||||

| 4 | 3×35+1×16 | 7/2.52 | 7.56 | 0.9 | 25×0.20 | 1 | 47×1.6 | 1.8 | 31.1 | 1618.9 | 0.868 | |

| 7/1.66 | 4.98 | 0.7 | ||||||||||

| 5 | 3×35+2×16 | 7/2.52 | 7.56 | 0.9 | 25×0.20 | 1 | 50×1.6 | 1.8 | 32.4 | 1708.4 | 0.868 | |

| 7/1.66 | 4.98 | 0.7 | ||||||||||

| 7/1.66 | 4.98 | 0.7 | ||||||||||

| 4 | 3×50+1×25 | 10/2.52 | 7.2×10.8 | 1 | 55×0.20 | 1 | 47×1.6 | 1.9 | 30.9 | 1733 | 0.641 | |

| 7/2.16 | 6 | 0.9 | ||||||||||

| 5 | 3×50+2×25 | 10/2.52 | 5.0×14.3 | 1 | 55×0.20 | 1 | 46×1.6 | 2 | 30.7 | 1811.6 | 0.641 | |

| 7/2.16 | 6 | 0.9 | ||||||||||

| 7/2.16 | 6 | 0.9 | ||||||||||

| 4 | 3×70+1×35 | 14/2.52 | 9.0×13.0 | 1.1 | 60×0.20 | 1.2 | 45×2.0 | 2.1 | 37.1 | 2470 | 0.443 | |

| 7/2.52 | 7 | 0.9 | ||||||||||

| 5 | 3×70+2×35 | 14/2.52 | 6.0×16.8 | 1.1 | 60×0.20 | 1.2 | 43×2.0 | 2.1 | 35.5 | 2505.9 | 0.443 | |

| 7/2.52 | 7 | 0.9 | ||||||||||

| 7/2.52 | 7 | 0.9 | ||||||||||

| 4 | 3×95+1×50 | 19/2.52 | 10.7×14.5 | 1.1 | 60×0.20 | 1.2 | 51×2.0 | 2.2 | 41.2 | 2979.2 | 0.32 | |

| 10/2.52 | 8.4 | 1 | ||||||||||

| 5 | 3×95+2×50 | 19/2.52 | 7.2×19.7 | 1.1 | 60×0.20 | 1.2 | 49×2.0 | 2.3 | 39.8 | 3079.3 | 0.32 | |

| 10/2.52 | 8.4 | 1 | ||||||||||

| 10/2.52 | 7.1×11.5 | 1 | ||||||||||

| 4 | 3×120+1×70 | 24/2.52 | 11.5×17.3 | 1.2 | 60×0.20 | 1.2 | 54×2.0 | 2.4 | 43.9 | 3427.9 | 0.253 | |

| 14/2.52 | 10 | 1.1 | ||||||||||

| 5 | 3×120+2×70 | 24/2.52 | 8.0×22.1 | 1.2 | 60×0.20 | 1.4 | 44×2.5 | 2.5 | 45.3 | 4098.5 | 0.253 | |

| 14/2.52 | 10 | 1.1 | ||||||||||

| 14/2.52 | 7.8×13.1 | 1.1 | ||||||||||

| 4 | 3×150+1×70 | 30/2.52 | 13.2×19.4 | 1.4 | 60×0.20 | 1.4 | 50×2.5 | 2.5 | 50.4 | 4502.6 | 0.206 | |

| 14/2.52 | 10 | 1.1 | ||||||||||

| 5 | 3×150+2×70 | 30/2.52 | 9.1×24.3 | 1.4 | 60×0.20 | 1.4 | 48×2.5 | 2.6 | 48.5 | 4625.4 | 0.206 | |

| 14/2.52 | 10 | 1.1 | ||||||||||

| 14/2.52 | 7.8×13.1 | 1.1 | ||||||||||

| 4 | 3×185+1×95 | 37/2.52 | 15.0×22.3 | 1.6 | 60×0.20 | 1.4 | 56×2.5 | 2.7 | 55.8 | 5306.2 | 0.164 | |

| 19/2.52 | 11.6 | 1.1 | ||||||||||

| 5 | 3×185+2×95 | 37/2.52 | 10.2×27.2 | 1.6 | 60×0.20 | 1.4 | 53×2.5 | 2.8 | 53.5 | 5455.2 | 0.164 | |

| 19/2.52 | 11.6 | 1.1 | ||||||||||

| 19/2.52 | 9.2×14.7 | 1.1 | ||||||||||

| 4 | 3×240+1×120 | 48/2.52 | 17.7×23.7 | 1.7 | 60×0.20 | 1.6 | 65×2.5 | 2.9 | 63.3 | 6488.1 | 0.125 | |

| 24/2.52 | 13 | 1.2 | ||||||||||

| 5 | 3×240+2×120 | 48/2.52 | 11.5×29.2 | 1.7 | 60×0.20 | 1.6 | 59×2.5 | 3 | 58.8 | 6541.3 | 0.125 | |

| 24/2.52 | 13 | 1.2 | ||||||||||

| 24/2.52 | 9.9×16.4 | 1.2 | ||||||||||

| 4 | 3×300+1×150 | 61/2.52 | 19.2×28.3 | 1.8 | 60×0.20 | 1.6 | 69×2.5 | 3 | 67.5 | 7439.9 | 0.1 | |

| 30/2.52 | 14.6 | 1.4 | ||||||||||

| 5 | 3×300+2×150 | 61/2.52 | 13.0×33.2 | 1.8 | 60×0.20 | 1.6 | 65×2.5 | 3.2 | 64.4 | 7725.7 | 0.1 | |

| 30/2.52 | 14.6 | 1.4 | ||||||||||

| 30/2.52 | 10.6×17.9 | 1.4 | ||||||||||

| 5 | 4×16+1×10 | 7/1.66 | 4.98 | 0.7 | 25×0.20 | 1 | 40×1.6 | 1.8 | 27 | 1273.6 | 1.91 | |

| 7/1.35 | 4.05 | 0.7 | ||||||||||

| 5 | 4×25+1×16 | 7/2.14 | 6.42 | 0.9 | 25×0.20 | 1 | 48×1.6 | 1.8 | 31.4 | 1643.9 | 1.2 | |

| 7/1.66 | 4.98 | 0.7 | ||||||||||

| 5 | 4×35+1×16 | 7/2.52 | 7.56 | 0.9 | 25×0.20 | 1 | 52×1.6 | 1.9 | 34.2 | 1904 | 0.868 | |

| 7/1.66 | 4.98 | 0.7 | ||||||||||

| 5 | 4×50+1×25 | 10/2.52 | 5.5×13.4 | 1 | 55×0.20 | 1.2 | 39×2.0 | 2.1 | 33.1 | 2200.8 | 0.641 | |

| 7/2.16 | 6 | 0.9 | ||||||||||

| 5 | 4×70+1×35 | 14/2.52 | 6.7×15.8 | 1.1 | 60×0.20 | 1.2 | 45×2.0 | 2.2 | 37.1 | 2708.3 | 0.443 | |

| 7/2.52 | 7 | 0.9 | ||||||||||

| 5 | 4×95+1×50 | 19/2.52 | 7.7×18.3 | 1.1 | 60×0.20 | 1.2 | 50×2.0 | 2.4 | 41 | 3280.9 | 0.32 | |

| 10/2.52 | 8.4 | 1 | ||||||||||

| 5 | 4×120+1×70 | 24/2.52 | 9.5×20.8 | 1.2 | 60×0.20 | 1.4 | 48×2.5 | 2.5 | 48.3 | 4472.7 | 0.253 | |

| 14/2.52 | 10 | 1.1 | ||||||||||

| 5 | 4×150+1×70 | 30/2.52 | 10.0×22.9 | 1.4 | 60×0.20 | 1.4 | 50×2.5 | 2.7 | 50.5 | 5015.5 | 0.206 | |

| 14/2.52 | 10 | 1.1 | ||||||||||

| 5 | 4×185+1×95 | 37/2.52 | 10.8×25.6 | 1.6 | 60×0.20 | 1.6 | 55×2.5 | 2.9 | 55.5 | 5927.2 | 0.164 | |

| 19/2.52 | 11.6 | 1.1 | ||||||||||

| 5 | 4×240+1×120 | 48/2.52 | 12.6×28.9 | 1.7 | 60×0.20 | 1.6 | 62×2.5 | 3.1 | 61.2 | 7118.7 | 0.125 | |

| 24/2.52 | 13 | 1.2 | ||||||||||

| 5 | 4×300+1×150 | 61/2.52 | 13.8×32.2 | 1.8 | 60×0.20 | 1.6 | 54×3.15 | 3.3 | 67.5 | 9131.5 | 0.1 | |

| 30/2.52 | 14.6 | 1.4 |

We are based in Henan, China, start from 2012,sell to Domestic Market(70.00%), Mid East(11.00%), South America(10.00%), Africa(3.00%), North America(2.00%), Southeast Asia(2.00%), Eastern Asia(00.00%), South Asia(00.00%). There are total about 101-200 people in our office.

Always a pre-production sample before mass production; Always final Inspection before shipment.

Wire, Cable

We have twenty years of experience in design and development

Accepted Delivery Terms: FOB,CFR,CIF,EXW;

Accepted Payment Currency: USD,EUR;

Accepted Payment Type: T/T,L/C,Money Gram,Western Union;

Language Spoken: English,Chinese,French

Most quotes are returned within 24 hours

Tests are divided into routine tests, sampling tests and type test items.

Routine tests:Tests carried out by the manufacturer on all manufactured lengths of finished cables to verify that all cables comply with specified requirements.

Routine test items:Conductor resistance measurement, voltage test.

Sampling tests:Tests carried out by the manufacturer on specimens of finished cables or on certain components taken from finished cables at specified frequencies to check whether the cables comply with specified requirements.

Sampling test items:Conductor inspection, dimensional inspection, thermal extension testing of insulation and elastomer sheaths.

Type test:Tests carried out on normal commercial principles before supply of a type of cable covered by this standard to demonstrate that the cable has satisfactory performance under the conditions of intended use.

Type testing includes electrical type testing and non-electrical type testing items.

Electrical type test items:1) Insulation resistance measurement at ambient temperature.2) Measurement of insulation resistance at maximum conductor temperature during normal operation.3) 4h voltage test.

Non-electrical type test items include insulation non-electrical type test and sheath non-electrical type test.

Insulation non-electrical type test items: Dimensional measurements、mechanical properties(tensile strength and Elongation at break)、High temperature pressure test、Low temperature performance、Thermal shock test、Thermal extension test and water absorption test, etc.

Sheath non-electrical type test items:Dimensional measurements、mechanical properties(tensile strength and Elongation at break)、High temperature pressure test、Low temperature performance、Weight loss test and thermal shock test, etc.

Product performance requirements and test methods comply with the provisions of standard GB/T 12706.1-2008.

1. Each cable should be accompanied by a certificate of product quality acceptance and a factory test report. The cable certificate should indicate Operating machine sequence number and insulation extrusion sequential number of the insulation extruder that produces the cable.

2. During on-site inspection. The contract goods arrive at the delivery location,after receiving the notice from the buyer, the seller shall go to the delivery location in a timely manner and organize with the buyer to inspect the model, specification, appearance, quantity, accompanying technical documents, packaging, etc. of the contract goods based on the waybill and packing list.

3. During on-site inspection,If the contract goods are damaged, defective, lacking or do not meet the quality standards and specifications agreed in the contract due to the seller's fault, the seller shall complete the repair, replacement or additional supply of equipment as soon as possible without affecting the progress of the project, all costs and delays incurred shall be borne by the seller. If any damage, defect or deficiency in the goods under contract is found to be due to the fault of the buyer, the seller shall repair, replace or replenish the corresponding parts as soon as possible after receiving notification from the buyer. The cost and delay of the construction period shall be borne by the buyer.

4. Sampling for inspection:Before the cables are shipped (or after the arrival of each batch of cables), the buyer has the right to conduct sampling work. The buyer or purchasers commission a third party to take samples of the contracted goods and send them to an authoritative inspection agency for inspection. If the contract goods sampled do not meet the contract requirements, the buyer has the right to expand the scope of random inspections in accordance with the contract ,and based on the test results and relevant provisions of the contract, require the seller to take remedial measures such as re-production, repair, replacement, etc. until the inspection is qualified or to unilaterally terminate the contract. All related expenses incurred during this period shall be borne by the seller. At the same time, penalties will be imposed in accordance with the corresponding penalties in the contract.

Refer to the former Ministry of power Industry, Ministry of Machinery Industry issued by the electricity Office (1995) No. 37 "Interim Provisions for the quality supervision of large power equipment", "General representative group working Regulations in large power equipment manufacturers"

Document witness, on-site witness and shutdown pending inspection, namely R point,W point , and H point.

After each manufacturing supervision content is completed, the supplier and the manufacturing supervision representative will complete the signature procedures on the witness form. The supplier shall submit one copy to the demander's manufacturing supervision representative.

R point:The supplier only needs to provide items of inspection or test records or reports, that is, document evidence.

W point:Inspection or test items attended by the purchaser’s manufacturing supervision representative, i.e. on-site witness

H point: When the supplier stops to wait for the inspection or test of the buyer's supervision representative, that is, the project is stopped for inspection.

Upon receipt of the witness notice, the demander shall promptly send a representative to the site of the supplier's inspection or test to participate in on-site witness or stop work for inspection. If the representative of the demander cannot attend on time, point W can be automatically converted to point R, but if point H is not agreed to be converted to point R by written notice of the demander, the supplier will not transfer to the next process and agree with the demander to change the witness time. If the buyer is still unable to participate on time after the change, the H point will be automatically converted to R point.

3.1 The supplier has the obligation to cooperate with the demander's manufacturing supervision and provide relevant information in a timely manner without incurring any costs.

3.2 The Supplier shall provide the demander's supervision representative with the convenience of work and life

3.3 The supplier shall inform the Buyer's representative of the equipment supervision project and time before witnessing the site or stopping work for inspection.

3.4 Demander's supervision representative has the right to check (borrow) the technical information related to the contract supervision equipment. If demander considers it necessary to copy and file, the supplier shall provide convenience.

3.5 The supplier shall provide the inspection and test records and reports to the supervision representative of the demander after the witness.