| Medium Voltage ABC Cable | ||

| Voltage: | 10kV | |

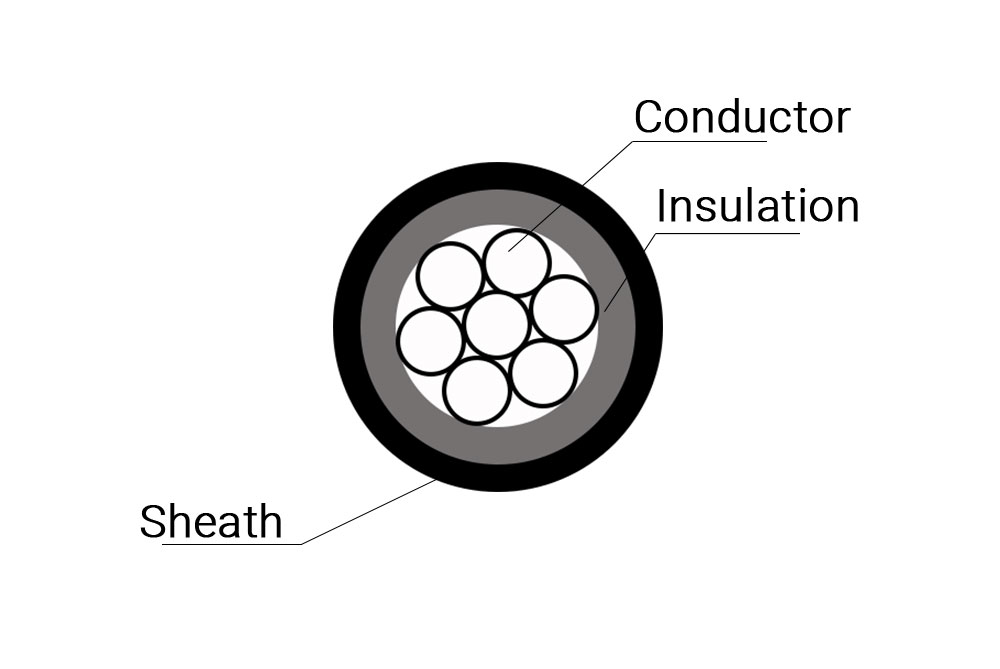

| Structure: | Conductor | ALUMINUM |

| Insulation | XLPE | |

| Armour | CAN | |

| Jacket | PVC | |

Overhead Transmission Line

Overhead lines are used for overhead fixed laying lines and service entrance conductor.

The overhead insulated cable has the advantages of simple structure, safety and reliability, excellent mechanical and physical properties and electrical properties, environmental resistance and ultraviolet resistance, etc., due to its insulation material is weather-resistant special overhead insulated cable material, the long-term allowable working temperature of the cable is as high as 70℃ or 90℃, and the electrical insulation performance is excellent, and the volume resistivity is more than 1.0×10^12Ω·m; In laying, the overhead insulated cable can reduce the laying gap, save the line corridor and reduce the voltage drop. It can reduce the occurrence of power supply accidents and ensure personal safety in use.

GB/T 14049-2008 Rated voltage 10kV overhead insulated cable GB/T 1179-2017 Round concentric gallows empty conductor

Rated Voltage: 10KV

The maximum allowable long-term operating temperature of the conductor is 90℃

Laying Temperature:The laying temperature of the cable should not be lower than -20℃.

Bending Radius:Bending radius should not be less than 20 times cable diameter (D).

GUOWANG CABLE GROUP

The weight of cables less than 80kg are allowed to be delivered in rings, and the delivery length of short sections of the cable shall not exceed 5% of the total length of the delivery, or any length of cable may be delivered according to the agreement between the parties.

The measurement error of delivery length is ±0.5%.

1.Cables in rolls and coils should be neatly wound and properly packed; The cable tray shall comply with the provisions of JB/T8137-1999; The cable ends should be securely sealed, and the cable ends extending out of the disk should be covered with a protective cover, the length of the cable ends extending out of the disk should be less than 300mm. 2.It should be labeled with a content on the package of the cable: manufacturer name, model, specification, rated voltage, length, quality, manufacturing date, standard number or certification mark, the correct rotation direction of the cable tray, etc. 3.Transport is generally in the form of vehicles and ships, and the cable must be firmly fixed during transport to avoid bumping or tipping over to cause damage to the cable or disc.

4.Do not lay the cable tray flat; It is strictly forbidden to drop the cable tray containing the cable from a height during transportation. 5.The finished cable should be stored in an environment where the temperature is between 0 and 40℃and the humidity is below 85%, so that it is not directly exposed to sunlight or rain, and should be properly ventilated to keep the environment dry.

The model, specification, length, delivery date, packing method and other necessary information of the cable should be correctly marked when ordering.

Cable should keep some distance from trees when it is being laid.

| Rated Voltage | Specification | Conductor | Outer Diameter Of Conductor(mm) | Insulation Thickness(mm) | Outer Diameter(mm) | Weight(kg/km) | Maximum Direct Current Resistance (MΩ/km) |

| 10KV | 10/2 | 6/1.47 1/1.5 |

4.1 | 3.4 | 12.1 | 138.6 | 3.08 |

| 16/3 | 6/1.86 1/1.85 |

5.2 | 3.4 | 13.2 | 174.9 | 1.91 | |

| 25/4 | 6/2.35 1/2.32 |

6.5 | 3.4 | 14.5 | 228.7 | 1.2 | |

| 35/6 | 6/2.76 1/2.72 |

7.6 | 3.4 | 15.6 | 281.1 | 0.868 | |

| 50/8 | 6/3.22 1/3.20 |

8.9 | 3.4 | 16.9 | 347.3 | 0.641 | |

| 70/10 | 6/3.87 1/3.80 |

10.7 | 3.4 | 18.7 | 452.1 | 0.443 | |

| 95/15 | 26/2.19 7/1.67 |

12.8 | 3.4 | 21.0 | 586.9 | 0.32 | |

| 95/20 | 24/2.28 7/1.85 |

13 | 3.4 | 21.2 | 616.9 | 0.32 | |

| 120/20 | 26/2.46 7/1.85 |

14.3 | 3.4 | 22.5 | 701.5 | 0.253 | |

| 150/20 | 24/2.84 7/1.85 |

15.7 | 3.4 | 23.9 | 792.1 | 0.206 | |

| 185/25 | 24/3.18 7/2.10 |

17.6 | 3.4 | 25.8 | 960.3 | 0.164 | |

| 185/30 | 26/3.05 7/2.32 |

17.8 | 3.4 | 26.0 | 1005.2 | 0.164 | |

| 240/30 | 24/3.64 7/2.40 |

20.1 | 3.4 | 28.3 | 1206.2 | 0.125 | |

| 300/25 | 48/2.88 7/2.22 |

22.1 | 3.4 | 30.3 | 1358.2 | 0.1 |

We are based in Henan, China, start from 2012,sell to Domestic Market(70.00%), Mid East(11.00%), South America(10.00%), Africa(3.00%), North America(2.00%), Southeast Asia(2.00%), Eastern Asia(00.00%), South Asia(00.00%). There are total about 101-200 people in our office.

Always a pre-production sample before mass production; Always final Inspection before shipment.

Wire, Cable

We have twenty years of experience in design and development

Accepted Delivery Terms: FOB,CFR,CIF,EXW;

Accepted Payment Currency: USD,EUR;

Accepted Payment Type: T/T,L/C,Money Gram,Western Union;

Language Spoken: English,Chinese,French

Most quotes are returned within 24 hours

Test item:Conductor DC resistance, AC voltage withstand test.

Test item:conductor structure, insulation thickness, shielding structure, 4h AC voltage test, thermal extension test, stranding pitch diameter ratio and stranding direction, single wire performance after stranding.

Test item:Partial discharge test, bending test, impulse voltage and AC voltage test, 4h AC voltage test, insulation mechanical and physical properties test, insulation mechanical properties test before and after aging, thermal extension test, semi-conductive layer stripping test, printed mark friction test, stranding pitch diameter ratio and twist direction, single wire performance after stranding.

Product performance requirements and test methods in accordance with the provisions of standard GB/T 14049-2008.

1.The products shall be inspected by the quality inspection department of the manufacturer before leaving the factory, and the products shall be accompanied by the quality inspection certificate.

2.The product shall be tested and accepted according to the regulations.

3.The sampling quantity of each batch shall be stipulated by the agreement between the two parties, and it shall be specified by the manufacturer if the customer does not request it.

4.If the test result of the sampling project is unqualified, the sample should be doubled, and if the second test of the unqualified project is still unqualified, it should be 100% inspected.

5.If there is any dispute between the manufacturer and the user on acceptance, arbitration test shall be conducted by an authority recognized by both parties.

1.The supplier has the obligation to cooperate with the purchaser to provide relevant information in a timely manner without incurring any costs.

2.The supplier shall provide the convenient work and life to purchaser’s supervision representative.

3.The supplier shall inform the representative of the purchaser of the equipment supervision project and time before witnessing the site or stopping work for inspection.

4.The supervision representative of purchaser has the right to check the technical information related to the contract supervision equipment. If purchaser considers it necessary to copy and file, the supplier shall provide convenience.

5. The supplier shall provide relevant inspection, test records and reports to the supervision representative of the purchaser after the witness.