| H1Z2Z2-K | ||

| Voltage: | 1000V AC, or 1500V DC | |

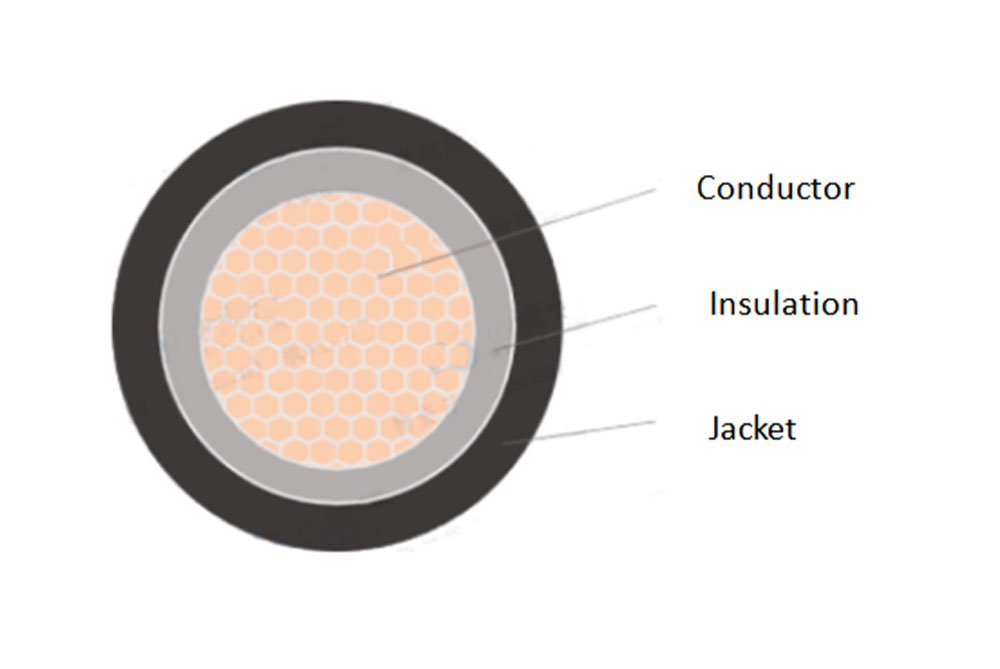

| Structure: | Conductor | Tinned Copper |

| Insulation | Low smoke halogen-free (LSHF), XLPO | |

| Jacket | Low smoke halogen-free (LSHF), XLPO | |

| Feature | Solar Wire Cable | |

H1Z2Z2-K intended for the interconnection within photovoltaic systems such as solar panel arrays. Suitable for fixed installations, internal and external, within conduit or systems.

Impact tested - Suitable for direct burial. For installations where fire, smoke emissions and toxic fumes create a potential risk to life and equipment. Water resistant to AD8.

Suitable for photovoltaic devices, For example, HD 60364-7-712. It can be used permanently both outdoors and indoors, and can be freely moved, freely hung and fixed. It can also be installed in conduits and troughs under gypsum and in electrical appliances. Suitable for in-plant/field applications with protective insulation (protection Class II). According to HD 60364-5-52, inherent protection against short circuit and ground faults

The product has the characteristics of high temperature resistance, ozone resistance, UV resistance, short time overload ability, long life, oil resistance, wear resistance, corrosion resistance, high tensile strength and so on

EN 50618, TÜV 2 PfG 1169/08.2007, EN 50288-3-7, EN 60068-2-78, EN 50395

Flame retardant to IEC/EN 60332-1-2

Low Smoke Zero Halogen to IEC/EN 60754-1/2,

IEC/EN 61034-1/2, EN 50267-2-2

Ozone and UV Resistant to EN 60811-403, EN 50396,

EN ISO 4892-1/3,

Water Resistant to AD8

Rated voltage:The power frequency AC rated voltage is 0.45/0.75kV, and the maximum voltage of the AC system should not exceed 1.0kV.

Cable conductor allows the highest working temperature120 ℃ for a long time. ;During a short circuit, the maximum temperature of the cable conductor shall not exceed 250°C and the duration shall not exceed 5s.

60 ° C.

Maximum storage temperature: +40℃; .

Minimum temperature for installation and transportation: -25℃

The recommended bending radius is shown in Table 3, EN 50565-1:2014

The insulated cable core is preferably black

The sheathing shall be black unless otherwise agreed by the manufacturer and the customer. The surface of the cable jacket shall be printed with the name of the manufacturer or its code, the year of manufacture and the product mark. Mark spacing should not be greater than 550mm. Signs should be legible and not easily erased.

The standard cable length is 500m, 1000m, and 2000m. Allow the cable manufacturer and the user to deliver the goods in accordance with the length and deviation stipulated by the mutual agreement

The measurement error of delivery length should not exceed ±0.5%.

Cables should be packed in circles or trays and arranged neatly

the diameter of the cable circle or the diameter of the packaging drum should not be less than 30 times the diameter of the cable.The cable should be wrapped with plastic film or other materials after it has been coiled or assembled

Each plate/circle cable should be attached to the product certificate, the certificate should be marked with the manufacturer's name, cable model, cable length, weight, factory number, manufacturing date, this standard number and other content

transportation

During cable transportation, measures should be taken to prevent the cable coil/ring from impact, mechanical damage and sun and rain

Cables should be stored in a dry, cool indoor warehouse away from fire sources

Necessary information of ordering such as cable model, specification, length, packaging method, date of delivery, etc. should be correctly indicated.

Maximum storage temperature:+40℃

Minimum temperature for installation and transportation:-25℃

| Rated Voltage | No.of CORES | specification | conductor structure | outer diameter of conductor(mm) | insulation thickness(mm) | Sheath thickness(mm) | reference outer diameter(mm) | reference weight(mm) | DC RESISTANCE (OHM/KM) | 20℃ Minimum insulation resistance at operating temperature(OHM-KM) | 90℃ Minimum insulation resistance at operating temperature(OHM-KM) | Ac test voltage(KV/min) | Dc test voltage(KV/min) |

| DC/1500V | 1 | 1×1.5 | 30/0.25 | 1.56 | 0.7 | 0.8 | 4.6 | 36.04 | 13.7 | 860 | 0.86 | 6.5/5 | 15/5 |

| 1×2.5 | 49/0.25 | 2 | 0.7 | 0.8 | 5 | 48 | 8.21 | 690 | 0.69 | 6.5/5 | 15/5 | ||

| 1×4 | 56/0.3 | 2.56 | 0.7 | 0.8 | 5.6 | 66.02 | 5.09 | 580 | 0.58 | 6.5/5 | 15/5 | ||

| 1×6 | 84/0.3 | 3.54 | 0.7 | 0.8 | 6.5 | 95.2 | 3.39 | 500 | 0.5 | 6.5/5 | 15/5 | ||

| 1×10 | 77/0.4 | 4.56 | 0.7 | 0.8 | 7.6 | 143.7 | 1.95 | 420 | 0.42 | 6.5/5 | 15/5 | ||

| 1×16 | 119/0.4 | 5.67 | 0.7 | 0.9 | 8.9 | 197.27 | 1.24 | 340 | 0.34 | 6.5/5 | 15/5 | ||

| 1×25 | 189/0.4 | 7.1 | 0.9 | 1 | 10.9 | 307.31 | 0.795 | 340 | 0.34 | 6.5/5 | 15/5 | ||

| 1×35 | 259/0.4 | 8.4 | 0.9 | 1.1 | 12.4 | 404.51 | 0.565 | 290 | 0.29 | 6.5/5 | 15/5 | ||

| 1×50 | 19/20/0.40 | 10.2 | 1 | 1.2 | 14.6 | 588.57 | 0.393 | 270 | 0.27 | 6.5/5 | 15/5 | ||

| 1×70 | 19/18/0.50 | 12.2 | 1.1 | 1.2 | 16.8 | 809.69 | 0.277 | 250 | 0.25 | 6.5/5 | 15/5 | ||

| 1×95 | 19/24/0.50 | 13.7 | 1.1 | 1.3 | 18.5 | 1037.01 | 0.21 | 220 | 0.22 | 6.5/5 | 15/5 | ||

| 1×120 | 19/32/0.50 | 16.7 | 1.2 | 1.3 | 21.7 | 1355.94 | 0.164 | 210 | 0.21 | 6.5/5 | 15/5 | ||

| 1×150 | 37/20/0.50 | 17.9 | 1.4 | 1.4 | 23.5 | 1638.31 | 0.132 | 210 | 0.21 | 6.5/5 | 15/5 | ||

| 1×185 | 37/24/0.50 | 19.6 | 1.6 | 1.6 | 26 | 1970.46 | 0.108 | 200 | 0.2 | 6.5/5 | 15/5 | ||

| 1×240 | 60/20/0.50 | 22.9 | 1.7 | 1.7 | 29.7 | 2601.63 | 0.0817 | 200 | 0.2 | 6.5/5 | 15/5 |

We are based in Henan, China, start from 2012,sell to Domestic Market(70.00%), Mid East(11.00%), South America(10.00%), Africa(3.00%), North America(2.00%), Southeast Asia(2.00%), Eastern Asia(00.00%), South Asia(00.00%). There are total about 101-200 people in our office.

Always a pre-production sample before mass production; Always final Inspection before shipment.

Wire, Cable

We have twenty years of experience in design and development

Accepted Delivery Terms: FOB,CFR,CIF,EXW;

Accepted Payment Currency: USD,EUR;

Accepted Payment Type: T/T,L/C,Money Gram,Western Union;

Language Spoken: English,Chinese,French

Most quotes are returned within 24 hours

The test is divided into routine test, sample test and type test

Tests carried out by the manufacturer on all manufactured lengths of the finished cable,To check whether all cables meet the specified requirements.

The test item is voltage test (1min), flame retardant test, smoke density

Tests carried out by the manufacturer on the finished cable or on certain components taken from the finished cable at a specified frequency to check whether the cable meets the specified requirements

Sampling test items: Conductor DC resistance, structural inspection, insulation thickness measurement, lining thickness measurement, metal shielding layer size measurement, armor layer size measurement, isolation sleeve thickness measurement, sheath thickness measurement, insulation thermal extension test, sheath thermal extension test

Tests carried out on normal commercial principles on cables prior to supply to demonstrate satisfactory performance under the conditions of intended use

Type test items:Insulation thickness, copper sheath resistance, copper sheath thickness, voltage test (15min), bending test, flattening test, fire resistance test

Product performance requirements and test methods comply with the provisions of standard GB/T 13033.1-2007.

Each cable should be accompanied by product quality acceptance certificate and factory test report

Field inspection.After the contract goods arrive at the place of delivery, the seller shall, upon receipt of the Buyer's notice, promptly arrive at the place of delivery to inspect together with the Buyer the type, specification, appearance, quantity, technical documents and packaging of the contract goods according to the waybill and packing list. The Buyer shall notify the Seller of the date of on-site arrival inspection 3 working days in advance, and provide convenience for the Seller's inspection personnel to work and live at the seller's own expense. If the seller does not send a representative to participate, the buyer's inspection results shall prevail. If the seller's personnel fail to arrive at the site on time during the inspection, the Buyer shall have the right to inspect by itself, and the inspection results and records shall be equally valid for both parties.

3、During on-site inspection, if the contract goods are damaged, defective, short or do not conform to the quality standards and specifications stipulated in the contract due to the reasons of the Seller, the Seller shall complete the repair, replacement or additional supply of the equipment as soon as possible on the principle of not affecting the progress of the project, and all costs arising therefrom and the responsibility for delay of the construction period shall be borne by the Seller. If any damage, defect or shortage of the Contract goods is found due to the reasons of the Buyer, the Seller shall repair, replace or make up the corresponding parts as soon as possible after receiving the notice of the Buyer. The cost and the responsibility for delay in construction shall be borne by the Buyer

4、Sampling for inspection. Before cable delivery (or after the arrival of each batch of cables), the Buyer has the right to carry out sampling work, and the Buyer or the buyer commissions a third party to take samples of the contract goods and send them to the authoritative inspection institution for inspection. If the sampled contract goods do not meet the requirements of the contract, the Buyer has the right to expand the scope of sampling inspection according to the contract, and according to the test results and relevant provisions of the contract, The Seller shall be required to take remedial measures such as re-production, repair and replacement until the inspection is qualified or unilaterally terminate the contract. All relevant expenses incurred during this period shall be borne by the Seller and shall be punished according to the corresponding penalties hereof.

Refer to the "Interim Provisions on Quality Supervision of Large Electric Power Equipment" and "Working Regulations of the General Representative Group in Large Electric Power Equipment Manufacturing Plants" issued by the former Ministry of Electric Power Industry and the Ministry of Machinery Industry.

Refer to DL/T 586-2008 "Technical Guidelines for Equipment Manufacturing Supervision"

GB/T 50319-2013 "Code for Supervision of Construction Projects", GB/T 19000-2016/ISO 9000:2015 "Quality Management and Quality Assurance" standards.

Relevant business terms and technical agreements in the equipment purchase contract signed between the user and the manufacturer, including legally binding documents, letters, correspondence, etc.

Product equipment drawings confirmed by the user and the manufacturer and modification notice issued by the design unit.

National standards, industry standards, and enterprise standards involved in technical documents and design drawings (subject to the latest version). If the standards used in technical documents and design drawings are inconsistent with each other, national standards, industry standards, and enterprise standards will be used in the derivation order.

When the design drawings are inconsistent with the quoted standards, the requirements in the standards shall prevail in principle, except for those with special requirements for parts and components.

Document witness, on-site witness and shutdown pending inspection, namely R point, W point, H point

After each manufacturing supervision content is completed, the supplier and the manufacturing supervision representative will complete the signature procedures on the witness form. The supplier shall submit one copy to the demander's manufacturing supervision representative

Point R: The supplier only needs to provide inspection or test records or report items, that is, document witness

Point W: Inspection or test items attended by the buyer’s supervision representative, that is, on-site witness

Point H: The supplier stops work at this point to wait for inspection or testing by the demander's manufacturing supervision representative, that is, the supplier stops work pending inspection.

After receiving the witness notice, the demander shall promptly send representatives to the supplier's inspection or testing site to participate in on-site witnessing or stop work pending inspection. If the representative of the demand side cannot attend on time, point W can be automatically converted to point R. However, if point H does not receive written notification from the demand side and agrees to be converted to point R, the supplier will not move to the next process on its own and agree with the demand side to change the witness time. . If the buyer still cannot participate on time after the change, point H will be automatically converted to point R.

3.1The supplier has the obligation to cooperate with the demander's supervision and provide relevant information in a timely manner without incurring any costs.

3.2The supplier provides work and life convenience to the demand-side manufacturing supervision representatives

3.3The supplier shall notify the demander's manufacturing supervision representative of the equipment manufacturing supervision items and time before witnessing on-site or suspending work for inspection.

3.4The demander's manufacturing supervision representative has the right to check (borrow) technical data related to the contract manufacturing supervision equipment. If the demander considers that it is necessary to copy and archive it, the supplier should provide convenience.

3.5The supplier shall provide the inspection and test records and reports to the supervision representative of the demander after the witness.