|

U-1000 RVFV – XAV XLPE PVC 0.6/1kV Cable |

||

|

Voltage: |

0.6/1kV |

|

|

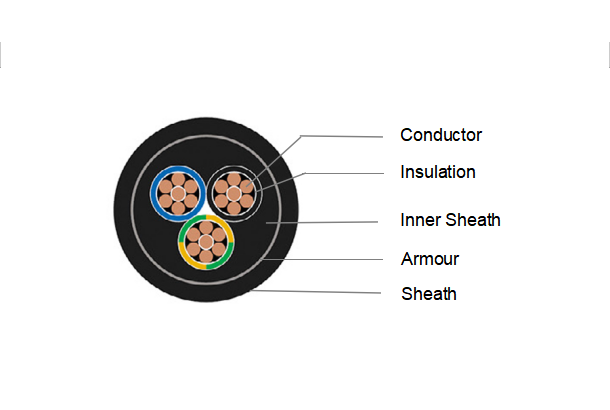

Structure: |

Conductor |

1.5mm² to 4mm²: Class 1 solid copper conductor |

|

Insulation |

XLPE (Cross-Linked Polyethylene) |

|

|

Inner Sheath |

PVC (Polyvinyl Chloride) |

|

|

Armour |

Two steel tapes |

|

|

Sheath |

PVC (Polyvinyl Chloride) |

|

|

Core Identification |

2 core: Blue Brown 3 core: Black Brown Grey 3 core including earth: Blue Brown Green/Yellow |

|

|

Sheath Colour |

Black Other colours available on request |

|

These U-1000 RVFV cables are suitable for direct burial without additional protection or for installation on cable trays or

in ducts where mechanical protection is necessary.

0.6/1kV

-10°C to +90°C

NF C 32-322

Flame Retardant according to NF C 32-070 C2、IEC 60332-1-2

1.5mm² to 4mm²: Class 1 solid copper conductor

6mm² and above: Class 2 stranded copper conductor

Class 2 stranded conductor available for these sizes on request

XLPE (Cross-Linked Polyethylene)

PVC (Polyvinyl Chloride)

Two steel tapes

PVC (Polyvinyl Chloride)

2 core: Blue Brown

3 core: Black Brown Grey

3 core including earth: Blue Brown Green/Yellow

Black

Other colours available on request

We have world-class testing facility, and made rigorous testing regime, every meter of cable before leaving the factory must go through strict testing, testing qualified products will be shipped to customers, effectively ensure product quality and meet customer requirements.

Guowang Cable actively implements the "carbon reduction" goal, strives to promote the green's low-carbon transformation, strengthens energy-saving and emission reduction technology innovation, and promotes the company's healthy and sustain-able development.

| NO. OF CORES |

NOMINAL CROSS SECTIONAL AREA mm² |

NOMINAL OVERALL DIAMETER mm |

NOMINAL WEIGHT kg/km |

|||

| 2 | 1.5 | 13 | 215 | |||

| 2 | 2.5 | 14 | 249 | |||

| 2 | 4 | 15.5 | 309 | |||

| 2 | 6 | 16.5 | 386 | |||

| 2 | 10 | 18.5 | 515 | |||

| 2 | 16 | 20.5 | 709 | |||

| 2 | 25 | 23.5 | 1063 | |||

| 3 | 2.5 | 14.5 | 274 | |||

| 3 | 4 | 16 | 352 | |||

| 3 | 6 | 17.5 | 447 | |||

| 3 | 10 | 19 | 624 | |||

| 3 | 16 | 22 | 849 | |||

| 3 | 25 | 25 | 1273 | |||

| 3 | 35 | 32.5 | 1644 | |||

| 3 | 50 | 37.5 | 2107 | |||

| 3 | 70 | 35 | 2862 | |||

| 3 | 95 | 40 | 4190 | |||

| 3 | 120 | 45 | 5176 | |||

| 3 | 150 | 50 | 6303 | |||

| 3 | 185 | 54 | 7698 | |||

| 3 | 240 | 63 | 9814 | |||

| 3 | 50 | 34.5 | 2560 | |||

| 3 | 70 | 40 | 3492 | |||

| 3 | 95 | 45 | 4790 | |||

| 3 | 120 | 50 | 5951 | |||

| 3 | 150 | 54 | 7090 | |||

| 5 | 1.5 | 15.5 | 301 | |||

| 5 | 2.5 | 17 | 373 | |||

| 5 | 4 | 18.5 | 480 | |||

| 5 | 6 | 20.5 | 638 | |||

| 5 | 10 | 22.5 | 900 | |||

| 5 | 16 | 26 | 1250 | |||

| 5 | 25 | 31 | 1903 | |||

| 5 | 35 | 32 | 2455 | |||

| NOMINAL CROSS SECTIONAL AREA mm² |

PERMISSIBLE CURRENT RATING WHEN BURIED Amps |

||||||||

| 2 core | 3 core | 5 core | |||||||

| 1.5 | 37 | - | 31 | ||||||

| 2.5 | 48 | 41 | 41 | ||||||

| 4 | 63 | 53 | 53 | ||||||

| 6 | 80 | 66 | 66 | ||||||

| 10 | 104 | 87 | 87 | ||||||

| 16 | 136 | 113 | 113 | ||||||

| 25 | 173 | 144 | 144 | ||||||

| 35 | - | 174 | 170 | ||||||

| 50 | - | 206 | - | ||||||

| 70 | - | 254 | - | ||||||

| 95 | - | 301 | - | ||||||

| 120 | - | 343 | - | ||||||

| 150 | - | 387 | - | ||||||

| 185 | - | 434 | - | ||||||

| 240 | - | 501 | |||||||

We are based in Henan, China, start from 2012,sell to Domestic Market(70.00%), Mid East(11.00%), South America(10.00%), Africa(3.00%), North America(2.00%), Southeast Asia(2.00%), Eastern Asia(00.00%), South Asia(00.00%). There are total about 101-200 people in our office.

Always a pre-production sample before mass production; Always final Inspection before shipment.

Wire, Cable

We have twenty years of experience in design and development

Accepted Delivery Terms: FOB,CFR,CIF,EXW;

Accepted Payment Currency: USD,EUR;

Accepted Payment Type: T/T,L/C,Money Gram,Western Union;

Language Spoken: English,Chinese,French

Most quotes are returned within 24 hours

routine tests:Tests carried out by the manufacturer on all manufactured lengths of finished cables to verify that all cables comply with specified requirements.

Routine test items:Conductor resistance measurement, voltage test.

sampling tests:Tests carried out by the manufacturer on specimens of finished cables or on certain components taken from finished cables at specified frequencies to check whether the cables comply with specified requirements.

Sampling test items:Conductor inspection, dimensional inspection, thermal extension testing of insulation and elastomer sheaths.

Type test:Tests carried out on normal commercial principles before supply of a type of cable covered by this standard to demonstrate that the cable has satisfactory performance under the conditions of intended use.

Type testing includes electrical type testing and non-electrical type testing items.

Electrical type test items:1) Insulation resistance measurement at ambient temperature.2) Measurement of insulation resistance at maximum conductor temperature during normal operation.3) 4h voltage test.

Non-electrical type test items include insulation non-electrical type test and sheath non-electrical type test.

Insulation non-electrical type test items: Dimensional measurements、mechanical properties(tensile strength and Elongation at break)、High temperature pressure test、Low temperature performance、Thermal shock test、Thermal extension test and water absorption test, etc.

Sheath non-electrical type test items:Dimensional measurements、mechanical properties(tensile strength and Elongation at break)、High temperature pressure test、Low temperature performance、Weight loss test and thermal shock test, etc.

Product performance requirements and test methods comply with the provisions of standard GB/T 12706.1-2008.

1. Each cable should be accompanied by a certificate of product quality acceptance and a factory test report. The cable certificate should indicate Operating machine sequence number and insulation extrusion sequential number of the insulation extruder that produces the cable.

2. During on-site inspection. The contract goods arrive at the delivery location,after receiving the notice from the buyer, the seller shall go to the delivery location in a timely manner and organize with the buyer to inspect the model, specification, appearance, quantity, accompanying technical documents, packaging, etc. of the contract goods based on the waybill and packing list.

3. During on-site inspection,If the contract goods are damaged, defective, lacking or do not meet the quality standards and specifications agreed in the contract due to the seller's fault, the seller shall complete the repair, replacement or additional supply of equipment as soon as possible without affecting the progress of the project, all costs and delays incurred shall be borne by the seller. If any damage, defect or deficiency in the goods under contract is found to be due to the fault of the buyer, the seller shall repair, replace or replenish the corresponding parts as soon as possible after receiving notification from the buyer. The cost and delay of the construction period shall be borne by the buyer.

4. Sampling for inspection:Before the cables are shipped (or after the arrival of each batch of cables), the buyer has the right to conduct sampling work. The buyer or purchasers commission a third party to take samples of the contracted goods and send them to an authoritative inspection agency for inspection. If the contract goods sampled do not meet the contract requirements, the buyer has the right to expand the scope of random inspections in accordance with the contract ,and based on the test results and relevant provisions of the contract, require the seller to take remedial measures such as re-production, repair, replacement, etc. until the inspection is qualified or to unilaterally terminate the contract. All related expenses incurred during this period shall be borne by the seller. At the same time, penalties will be imposed in accordance with the corresponding penalties in the contract.

Refer to the former Ministry of power Industry, Ministry of Machinery Industry issued by the electricity Office (1995) No. 37 "Interim Provisions for the quality supervision of large power equipment", "General representative group working Regulations in large power equipment manufacturers"

Document witness, on-site witness and shutdown pending inspection, namely R point,W point , and H point.

After each manufacturing supervision content is completed, the supplier and the manufacturing supervision representative will complete the signature procedures on the witness form. The supplier shall submit one copy to the demander's manufacturing supervision representative.

R point:The supplier only needs to provide items of inspection or test records or reports, that is, document evidence.

W point:Inspection or test items attended by the purchaser’s manufacturing supervision representative, i.e. on-site witness

H point: When the supplier stops to wait for the inspection or test of the buyer's supervision representative, that is, the project is stopped for inspection.

Upon receipt of the witness notice, the demander shall promptly send a representative to the site of the supplier's inspection or test to participate in on-site witness or stop work for inspection. If the representative of the demander cannot attend on time, point W can be automatically converted to point R, but if point H is not agreed to be converted to point R by written notice of the demander, the supplier will not transfer to the next process and agree with the demander to change the witness time. If the buyer is still unable to participate on time after the change, the H point will be automatically converted to R point.

3.1 The supplier has the obligation to cooperate with the demander's manufacturing supervision and provide relevant information in a timely manner without incurring any costs.

3.2 The Supplier shall provide the demander's supervision representative with the convenience of work and life

3.3 The supplier shall inform the Buyer's representative of the equipment supervision project and time before witnessing the site or stopping work for inspection..

3.4 Demander's supervision representative has the right to check (borrow) the technical information related to the contract supervision equipment. If demander considers it necessary to copy and file, the supplier shall provide convenience.

3.5 The supplier shall provide the inspection and test records and reports to the supervision representative of the demander after the witness.