| RG16H1OR12 Three Core MV Copper Cable | ||

| Voltage: | 1.8/3kV 3.6/6kV 6/10kV 8.7/15kV 12/20kV 18/30kV 26/45kV | |

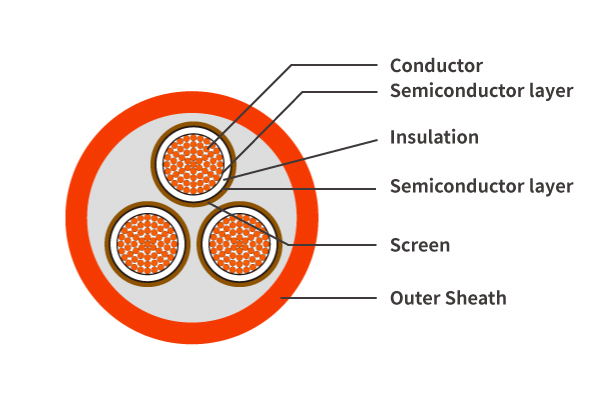

| Structure: | Conductor | class2, compact stranded wire, plain copper |

| Semiconductor layer | extruded (only cables Uo/U ≥ 6/10 kV) | |

| Insulation | HEPR rubber, G16 quality, Pb free | |

| Semiconductor layer | Hextruded, cold stripping (only cables Uo/U ≥ 6/10 kV) | |

| Identification of phases | threads or colored bands | |

| Inner sheath | PVC based compound extruded, penetrating between the cores | |

| Screen | plain copper tapes wrapped | |

| Outer Sheath | PVC based compound, R12 quality | |

| Sheath Colour | red | |

Suitable for energy transmission between transformer rooms and big power users. For laying on air, into tube or open pass.Can be laid underground, also if not protected, complying with art. 4.3.11 of CEI 11-17 standard.The cable is suitable for the supply of electricity in buildings and other civil engineering works.

1.8/3kV 3.6/6kV 6/10kV 8.7/15kV 12/20kV 18/30kV 26/45kV

ISO 4892-2:2013 / IEC 60811-501:2012 / 1000h

Maximun operating temperature:+90°C

Maximun short circuit temperature:+250°C

Min. operating temperature (without mechanical shocks):-15°C

12 D

CEI 20-13, IEC 60502 CEI 20-16 (IEC 60840 per 26/45 kV)

EN 50575:2014 + EN 50575/A1:2016 (IEC 60332-1-2)

class2, compact stranded wire, plain copper

extruded (only cables Uo/U ≥ 6/10 kV)

HEPR rubber, G16 quality, Pb free

Hextruded, cold stripping (only cables Uo/U ≥ 6/10 kV)

threads or colored bands

PVC based compound extruded, penetrating between the cores

plain copper tapes wrapped

PVC based compound, R12 quality

red

We have world-class testing facility, and made rigorous testing regime, every meter of cable before leaving the factory must go through strict testing, testing qualified products will be shipped to customers, effectively ensure product quality and meet customer requirements.

Guowang Cable actively implements the "carbon reduction" goal, strives to promote the green's low-carbon transformation, strengthens energy-saving and emission reduction technology innovation, and promotes the company's healthy and sustain-able development.

| Rated Voltage | Formation | Approx. conductor Ø | Average insulation thickness | Approx. external Ø | Approx. cable weight | Current rating A | |

| n° x mm2 | mm | mm | mm | kg/km | in air | buried* | |

| 1.8/3 kV | 3 x 10 | 4 | 2 | 22.7 | 895 | 85 | 93 |

| 3 x 16 | 4.8 | 2 | 24 | 1135 | 109 | 120 | |

| 3 x 25 | 6 | 2 | 26.5 | 1520 | 145 | 155 | |

| 3 x 35 | 7 | 2 | 29 | 1880 | 175 | 185 | |

| 3 x 50 | 8.1 | 2 | 31.3 | 2330 | 208 | 216 | |

| 3 x 70 | 9.7 | 2 | 35.2 | 3150 | 260 | 265 | |

| 3 x 95 | 11.4 | 2 | 39.2 | 4100 | 318 | 315 | |

| 3 x 120 | 12.9 | 2 | 42.8 | 5020 | 367 | 360 | |

| 3 x 150 | 14.3 | 2 | 46.1 | 6040 | 415 | 400 | |

| 3 x 185 | 16 | 2 | 49.9 | 7295 | 476 | 453 | |

| 3 x 240 | 18.3 | 2 | 55.7 | 9355 | 555 | 520 | |

| 3 x 300 | 21 | 2 | 61.5 | 11540 | 635 | 585 | |

| 3 x 400 | 23.2 | 2 | 67.1 | 14650 | 716 | 651 | |

| 3.6/6kV | 3 x 10 | 4 | 3 | 26.6 | 1180 | 85 | 93 |

| 3 x 16 | 4.8 | 3 | 28.5 | 1480 | 109 | 120 | |

| 3 x 25 | 6 | 3 | 31.2 | 1875 | 145 | 153 | |

| 3 x 35 | 7 | 3 | 33.5 | 2250 | 175 | 183 | |

| 3 x 50 | 8.1 | 3 | 36.2 | 2790 | 211 | 216 | |

| 3 x 70 | 9.7 | 3 | 39.9 | 3610 | 262 | 263 | |

| 3 x 95 | 11.4 | 3 | 43.9 | 4590 | 318 | 315 | |

| 3 x 120 | 12.9 | 3 | 47.7 | 5580 | 370 | 359 | |

| 3 x 150 | 14.3 | 3 | 51 | 6640 | 415 | 400 | |

| 3 x 185 | 16 | 3 | 54.8 | 7940 | 477 | 451 | |

| 3 x 240 | 18.3 | 3 | 60.6 | 10060 | 555 | 518 | |

| 3 x 300 | 21 | 3 | 66.4 | 12330 | 635 | 583 | |

| 3 x 400 | 23.2 | 3 | 72 | 15490 | 717 | 651 | |

| 6/10kV | 3 x 10 | 4 | 3.4 | 33.2 | 1670 | 73 | 78 |

| 3 x 16 | 4.8 | 3.4 | 35.1 | 1975 | 107 | 112 | |

| 3 x 25 | 6 | 3.4 | 37.8 | 2435 | 145 | 149 | |

| 3 x 35 | 7 | 3.4 | 40.3 | 2865 | 175 | 178 | |

| 3 x 50 | 8.1 | 3.4 | 42.6 | 3395 | 208 | 210 | |

| 3 x 70 | 9.7 | 3.4 | 46.9 | 4350 | 260 | 257 | |

| 3 x 95 | 11.4 | 3.4 | 50.7 | 5375 | 316 | 307 | |

| 3 x 120 | 12.9 | 3.4 | 55.1 | 6470 | 365 | 350 | |

| 3 x 150 | 14.3 | 3.4 | 58.4 | 7585 | 407 | 390 | |

| 3 x 185 | 16 | 3.4 | 62.3 | 8990 | 469 | 440 | |

| 3 x 240 | 18.3 | 3.4 | 69.3 | 11365 | 550 | 510 | |

| 3 x 300 | 21 | 3.4 | 75.1 | 13725 | 630 | 580 | |

| 3 x 400 | 23.2 | 3.4 | 80.8 | 14275 | 720 | 655 | |

| 8.7/15kV | 3 x 16 | 4.8 | 4.5 | 40.3 | 2455 | 98 | 101 |

| 3 x 25 | 6 | 4.5 | 42.8 | 2935 | 145 | 145 | |

| 3 x 35 | 7 | 4.5 | 45.2 | 3375 | 177 | 173 | |

| 3 x 50 | 8.1 | 4.5 | 47.8 | 3965 | 210 | 204 | |

| 3 x 70 | 9.7 | 4.5 | 51.8 | 4950 | 262 | 250 | |

| 3 x 95 | 11.4 | 4.5 | 55.9 | 6040 | 315 | 298 | |

| 3 x 120 | 12.9 | 4.5 | 59.8 | 7450 | 361 | 339 | |

| 3 x 150 | 14.3 | 4.5 | 63.1 | 8305 | 407 | 378 | |

| 3 x 185 | 16 | 4.5 | 67.4 | 9790 | 470 | 429 | |

| 3 x 240 | 18.3 | 4.5 | 73.4 | 12135 | 550 | 500 | |

| 3 x 300 | 21 | 4.5 | 80.2 | 15025 | 630 | 565 | |

| 12/20kV | 3 x 16 | 4.8 | 3.4 | 39.5 | 2805 | 105 | 111 |

| 3 x 25 | 6 | 3.4 | 41.4 | 3055 | 143 | 145 | |

| 3 x 35 | 7 | 3.4 | 44.9 | 3805 | 170 | 172 | |

| 3 x 50 | 8.1 | 3.4 | 47.4 | 4415 | 205 | 203 | |

| 3 x 70 | 9.7 | 3.4 | 51.5 | 5415 | 253 | 250 | |

| 3 x 95 | 11.4 | 3.4 | 55.5 | 6545 | 305 | 296 | |

| 3 x 120 | 12.9 | 3.4 | 60.1 | 7855 | 353 | 375 | |

| 3 x 150 | 14.3 | 3.4 | 63.8 | 9000 | 393 | 375 | |

| 3 x 185 | 16 | 3.4 | 67.9 | 10510 | 447 | 425 | |

| 3 x 240 | 18.3 | 3.4 | 74.9 | 13005 | 525 | 490 | |

| 3 x 300 | 21 | 3.4 | 80.5 | 15460 | 595 | 550 | |

| 18/30kV | 3 x 25 | 7 | 8 | 62 | 5815 | 177 | 174 |

| 3 x 50 | 8.1 | 8 | 64.1 | 6165 | 210 | 205 | |

| 3 x 70 | 9.7 | 8 | 67.9 | 7265 | 260 | 250 | |

| 3 x 95 | 11.4 | 8 | 71.9 | 8520 | 315 | 300 | |

| 3 x 120 | 12.9 | 8 | 77 | 9975 | 360 | 340 | |

| 3 x 150 | 14.3 | 8 | 80.4 | 11285 | 405 | 380 | |

| 3 x 185 | 16 | 8 | 84.1 | 12625 | 465 | 430 | |

| 3 x 240 | 18.3 | 8 | 90.3 | 15260 | 545 | 496 | |

| 26/45kV | 3 x 70 | 9.7 | 10.3 | 81.7 | 8650 | 255 | 241 |

| 3 x 95 | 11.4 | 10.3 | 85.6 | 9980 | 308 | 288 | |

| 3 x 120 | 12.9 | 10 | 87.8 | 12395 | 353 | 327 | |

| 3 x 150 | 14.3 | 9.5 | 89.4 | 13405 | 398 | 366 | |

We are based in Henan, China, start from 2012,sell to Domestic Market(70.00%), Mid East(11.00%), South America(10.00%), Africa(3.00%), North America(2.00%), Southeast Asia(2.00%), Eastern Asia(00.00%), South Asia(00.00%). There are total about 101-200 people in our office.

Always a pre-production sample before mass production; Always final Inspection before shipment.

Wire, Cable

We have twenty years of experience in design and development

Accepted Delivery Terms: FOB,CFR,CIF,EXW;

Accepted Payment Currency: USD,EUR;

Accepted Payment Type: T/T,L/C,Money Gram,Western Union;

Language Spoken: English,Chinese,French

Most quotes are returned within 24 hours

Cable tests are divided into ex-factory test and type test.

Ex-factory inspection includes 100% inspection and sampling inspection.

100% inspection items: conductor resistance measurement; Partial discharge test; Voltage test.

Sampling inspection shall be carried out on the cable after 100% inspection items have been completed and passed.

Sampling inspection items: Concentricity of insulation: Conductor inspection; Dimensional inspection; Voltage test; Thermal extension test of XLPE insulation.

Type test sample cables should be randomly selected from the cables that have passed the factory inspection.

Electrical type test items: bending test and subsequent partial discharge test; Tan delta measurement; Thermal cycle test and subsequent partial discharge test; Impulse voltage test and subsequent power frequency voltage test; 4h voltage test.

Non-electrical type test items: measurement of insulation thickness; Measurement of non-metal sheath thickness; Mechanical properties test before and after insulation aging; Mechanical properties test of non-metal sheath before and after aging; Additional aging tests for finished cable segments; ST2 type PVC sheath weight loss test; High temperature pressure test of insulation and non-metal sheathing; Low temperature performance test of PVC sheath; Cracking resistance test of PVC sheath (thermal shock test); Insulation water absorption test; Non-flame delay test of single cable; XLPE insulation shrinkage test; Strippability test of insulation shield; Water permeation test.

Product performance requirements and test methods are in accordance with the provisions of standard GB/T 12706.3-2008.

1.The purpose of the performance acceptance test is to check whether all the properties of the contract products meet the requirements.

2.The site of performance acceptance test shall be the demander's site.

3.The performance acceptance test shall be carried out within 6 months after the 168-hour full load trial operation of the product, and the specific test time shall be determined by both parties through negotiation.

4.Installation of measuring points, primary components and local instruments required for performance acceptance test shall be provided by the supplier and cooperated by the demander. The supplier shall also provide the technical cooperation and personnel cooperation required for the test.

5.Content of performance acceptance test

In accordance with supplier quality assurance and test requirements.

6.Criteria for performance acceptance test

In accordance with supplier's quality assurance and test requirements.

7.The performance acceptance test shall be conducted by the demander and participated by the supplier. The test program shall be provided by the demander and determined after discussion with the supplier. The specific test shall be completed by the testing department approved by both parties.

8.Confirmation of performance acceptance test results

The performance acceptance test report shall be prepared by the testing unit, and the conclusions of the report shall be accepted by both parties. If there is any disagreement between the two parties on the results of the test, the two parties shall settle it through negotiation. If no agreement can be reached, it shall be submitted to the superior departments of both parties for negotiation.

9.When a performance acceptance test is conducted, if a party fails to send personnel to participate in the test after receiving the test notice from the other party, it shall be deemed to have agreed to the acceptance test results.

Reference to the former Ministry of Electric Power Industry, Ministry of Machinery Industry issued by the Office (1995) No. 37 document "Interim Provisions on Quality Supervision of Large Electric Power Equipment" , "Regulations on the Work of the General Representative Group in Large Electrical Equipment Manufacturing Plants".

Reference to DL/T 586-2008 "Technical Guidelines for Equipment Manufacturing Supervision".

GB/T 50319-2013 "Specifications for Construction Project Supervision", GB/T 19000-2016/ISO 9000:2015 "Quality Management and Quality Assurance" Standard.

The relevant commercial terms and technical agreements in the equipment purchase contract signed between the user and the manufacturer, including legally binding documents, letters, correspondence, etc.

Product equipment drawings confirmed by the user and the manufacturer and modification notice issued by the design unit.

National standards, industry standards, and enterprise standards involved in technical documents and design drawings (subject to the latest version). If the standards adopted by the technical documents and the design drawings are inconsistent with each other, the national standards, industry standards, and enterprise standards shall be adopted as the recurrence order.

When the design drawing is inconsistent with the referenced standard, the requirements in the standard shall prevail in principle, except for those with special requirements for parts.

Document witness, site witness and stoppage for inspection, namely R point, W point, H point.

Each time after the completion of the supervision content, the supplier and the supervision representative will perform the signature procedure on the witness form. The supplier shall deliver one copy to the demand's supervision representative.

R Point : The supplier only needs to provide items of inspection or test records or reports, that is, document witness.

W Point : Inspection or test items attended by the purchaser’s manufacturing supervision representative, that is, on-site witness.

H Point : The supplier stops work at this point to wait for inspection or testing by the demander's manufacturing supervision representative, that is, it stops work pending inspection.

After receiving the witness notice, the demander shall promptly send representatives to the supplier's inspection or testing site to participate in on-site witnessing or stop work pending inspection.If the demander's representative cannot attend on time, point W can be automatically converted to point H, but if point h is converted to point r without the demander's written notice, the supplier will not transfer to the next process and agree with the demander to change the witness time.If the buyer is still unable to participate on time after the change, the H point will be automatically converted to R point.

The supplier has the obligation to cooperate with the demander's manufacturing supervision and provide relevant information in a timely manner without incurring any costs.

The supplier shall provide the demander's supervision representative with convenience in work and life.

The supplier shall inform the representative of the buyer of the equipment supervision project and time before on-site witness or stopping work for inspection.

The demander's supervision representative has the right to check (borrow) the technical data related to the contract supervision equipment. If the demander deems it necessary to copy and file, the supplier shall provide convenience.

After witnessing, the supplier shall provide relevant inspection, test records and report data to the manufacturing supervision representative of the demander.