| H07ZZ-F LSZH Rubber cable | ||

| Voltage: | 450/750V | |

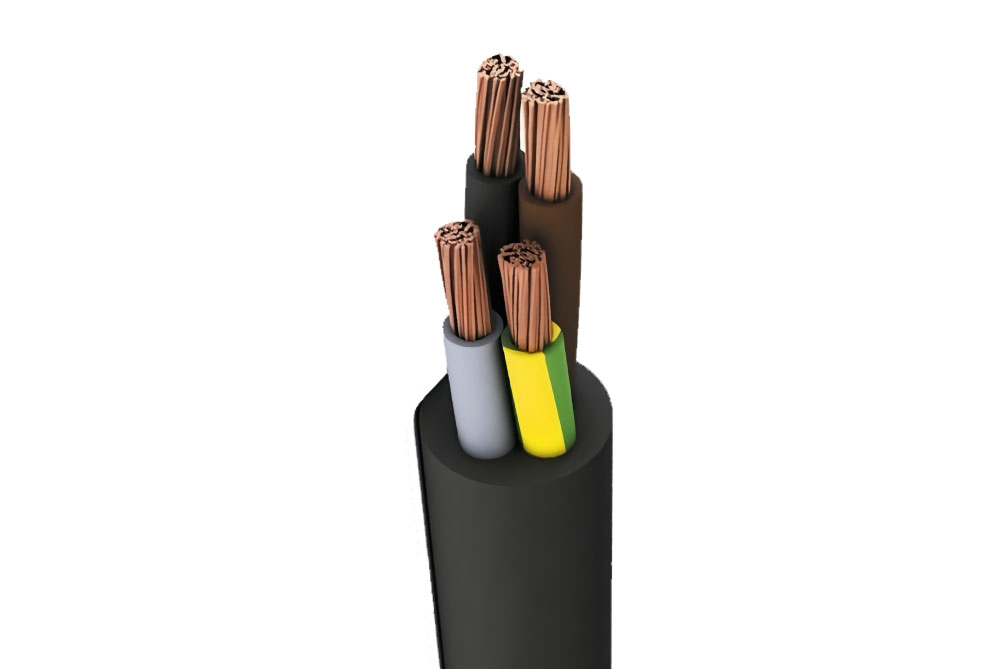

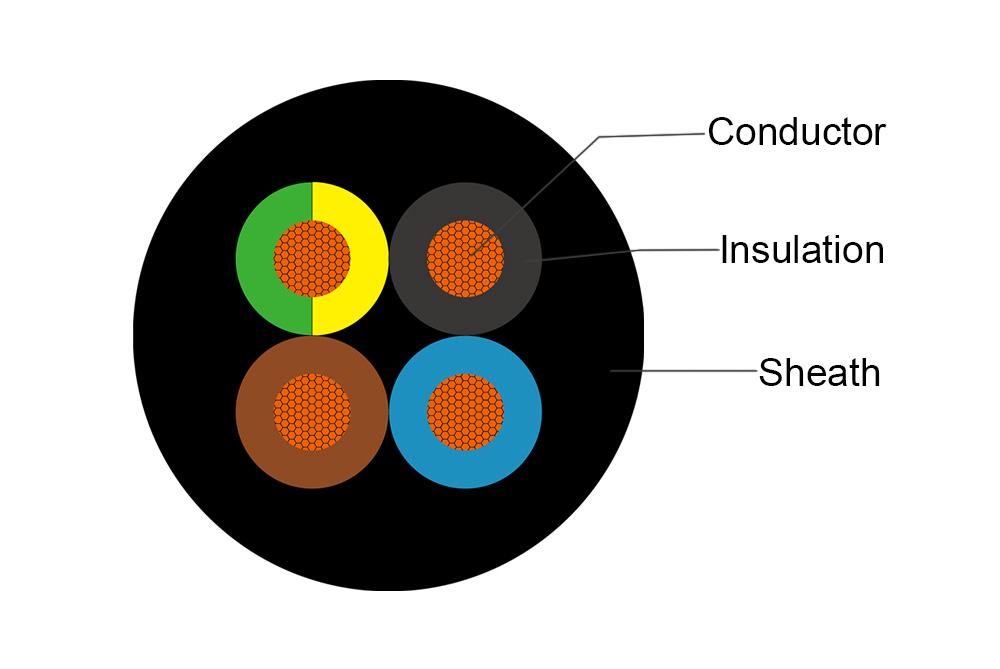

| Structure: | Conductor | Class 5 flexible copper conductor |

| Insulation | LSZH (Low Smoke Zero Halogen) cross-linked compound | |

| Jacket | LSZH (Low Smoke Zero Halogen) cross-linked compound | |

| Feature | LSZH Rubber cable | |

The H07ZZ-F cable is used across a broad range of applications across almost all industry sectors where installations are subjected to medium mechanical stresses such as supplying mobile power units, UPS connection, stage lighting and audio visual equipment. Flame Retardant according to IEC/EN 60332-3-10 and with its Low Smoke Zero Halogen insulation an oversheath, the H07ZZ-F is suitable for installations both indoors and outdoors, in buildings or industrial plants with a high density of people.

450/750V

Fixed: -20°C to +90°C

Flexed: -5°C to +50°C

Fixed: 4 x overall diameter

Flexed: 6 x overall diameter

Class 5 flexible copper conductor

LSZH (Low Smoke Zero Halogen) cross-linked compound

LSZH (Low Smoke Zero Halogen) cross-linked compound

1 core: Black

2 core: Blue Brown

3 core: Green/Yellow Blue Brown

4 core: Green/Yellow Brown Black Grey

5 core: Green/Yellow Blue Brown Black Grey

6 core and above: Black with White numbers

Green/Yellow

Black

EN 50525-3-21, HD 22-13, CEI 20-19 Part 13, EN 60228

Flame Retardant according to IEC/EN 60332-3-10

Low smokes/low smoke density in the event of fire according to IEC 61034

Ozone-resistant acc. to EN 50363-6, EN 60811-403, EN 50396-8.1.3

| NO. OF CORES |

NOMINAL CROSS SECTIONAL AREA mm2 |

AWG, approx. |

NOMINAL OVERALL DIAMETER mm |

NOMINAL WEIGHT kg/km |

| 1 | 1.5 | 16 | 6.4 | 63 |

| 1 | 2.5 | 14 | 7.1 | 76 |

| 1 | 4 | 12 | 8.1 | 107 |

| 1 | 6 | 10 | 8.85 | 140 |

| 1 | 10 | 8 | 10.7 | 213 |

| 1 | 16 | 6 | 12.1 | 291 |

| 1 | 25 | 4 | 14.25 | 415 |

| 1 | 35 | 2 | 16.1 | 539 |

| 1 | 50 | 1 | 18.55 | 740 |

| 1 | 70 | 2/0 | 20.95 | 989 |

| 1 | 95 | 3/0 | 23.4 | 1290 |

| 1 | 120 | 4/0 | 25.7 | 1592 |

| 1 | 150 | 300 kcmil | 28.3 | 1957 |

| 1 | 185 | 350 kcmil | 31 | 2350 |

| 1 | 240 | 500 kcmil | 34.45 | 3099 |

| 1 | 300 | 600 kcmil | 37.7 | 3687 |

| 1 | 400 | 750 kcmil | 42.1 | 4850 |

| 1 | 500 | 1000 kcmil | 46.65 | 5998 |

| 2 | 1 | 18 | 8.85 | 112 |

| 2 | 1.5 | 16 | 9.75 | 135 |

| 2 | 2.5 | 14 | 11.65 | 190 |

| 2 | 4 | 12 | 13.45 | 255 |

| 2 | 6 | 10 | 14.95 | 335 |

| 2 | 10 | 8 | 20.15 | 590 |

| 2 | 16 | 6 | 22.95 | 821 |

| 2 | 25 | 4 | 27.5 | 1172 |

| 3 | 1 | 18 | 9.5 | 125 |

| 3 | 1.5 | 16 | 10.55 | 129 |

| 3 | 2.5 | 14 | 12.45 | 250 |

| 3 | 4 | 12 | 14.45 | 330 |

| 3 | 6 | 10 | 16.05 | 440 |

| 3 | 10 | 8 | 21.65 | 800 |

| 3 | 16 | 6 | 24.7 | 1150 |

| 3 | 25 | 4 | 29.55 | 1680 |

| 3 | 35 | 2 | 33.2 | 2170 |

| 4 | 1 | 18 | 10.55 | 170 |

| 4 | 1.5 | 16 | 11.65 | 196 |

| 4 | 2.5 | 14 | 13.8 | 275 |

| 4 | 4 | 12 | 15.95 | 388 |

| 4 | 6 | 10 | 17.85 | 515 |

| 4 | 10 | 8 | 23.7 | 882 |

| 4 | 16 | 6 | 26.95 | 1234 |

| 4 | 25 | 4 | 32.75 | 1811 |

| 4 | 35 | 2 | 36.8 | 2365 |

| 4 | 50 | 1 | 42.6 | 3212 |

| 4 | 70 | 2/0 | 48.35 | 4320 |

| 4 | 95 | 3/0 | 54.7 | 5572 |

| 4 | 120 | 4/0 | 59.5 | 6930 |

| 4 | 150 | 300 kcmil | 65.5 | 8419 |

| 4 | 185 | 350 kcmil | 72 | 10165 |

| 4 | 240 | 500 kcmil | 81.5 | 13420 |

| 5 | 1 | 18 | 11.65 | 205 |

| 5 | 1.5 | 16 | 12.8 | 242 |

| 5 | 2.5 | 14 | 15.15 | 341 |

| 5 | 4 | 12 | 17.75 | 495 |

| 5 | 6 | 10 | 19.85 | 642 |

| 5 | 10 | 8 | 26 | 1090 |

| 5 | 16 | 6 | 29.85 | 1534 |

| 5 | 25 | 4 | 36.2 | 2291 |

| 5 | 35 | 2 | 39.5 | 2700 |

| 5 | 50 | 1 | 44.2 | 3730 |

| 5 | 70 | 2/0 | 50.4 | 5022 |

| 5 | 95 | 3/0 | 56.2 | 6520 |

| 5 | 120 | 4/0 | 64.1 | 8080 |

| 5 | 150 | 300 kcmil | 70.1 | 8660 |

| 7 | 1.5 | 16 | 16.7 | 355 |

| 12 | 1.5 | 16 | 20 | 660 |

| 19 | 1.5 | 16 | 27.5 | 788 |

| 27 | 1.5 | 16 | 31.5 | 1077 |

| 37 | 1.5 | 16 | 36.5 | 1358 |

Sampling inspection items: DC resistance of cable conductor; Voltage test of finished cable; Conductor monofilament diameter and deviation; The average thickness and thinnest point of the insulator; The average thickness and thinnest point of the sheath; Outer diameter of cable; Ovality; Length marker, error.

Test item:Dc resistance of cable conductor; Voltage test of finished cable; Conductor monofilament diameter and deviation; The average thickness and thinnest point of the insulator; The average thickness and thinnest point of the sheath; Outer diameter of cable; Cable ovality; Length mark, error; Change rate of tensile strength and elongation of insulation and sheath before and after aging; Insulated wire core withstand voltage test; Thermal extension test; Ozone resistance test; Finished cable bending test, etc.

The purpose of the performance acceptance test is to check whether all the properties of the contract products meet the requirements.

The site of performance acceptance test shall be the buyer's site.

The performance acceptance test shall be carried out within 6 months after the 168-hour full load trial operation of the product, and the specific test time shall be determined by both parties through negotiation.

Installation of measuring points, primary components and local instruments required for performance acceptance test shall be provided by the supplier and cooperated by the buyer. The supplier shall also provide the technical cooperation and personnel cooperation required for the test.

The content of performance acceptance test shall be in accordance with the supplier's quality assurance and test requirements.

The standard of performance acceptance test shall be in accordance with the supplier's quality assurance and test requirements.

The performance acceptance test shall be conducted by the buyer and participated by the supplier. The test program shall be provided by the buyer and determined after discussion with the supplier. The specific test shall be completed by the testing department approved by both parties.

Confirmation of performance acceptance test results The performance acceptance test report shall be prepared by the testing unit, and the conclusions of the report shall be recognized by both parties. If there is any disagreement between the two parties on the results of the test, the two parties shall settle it through negotiation. If no agreement can be reached, it shall be submitted to the superior departments of both parties for negotiation.

When a performance acceptance test is conducted, if a party fails to send personnel to participate in the test after receiving the test notice from the other party, it shall be deemed to have agreed to the acceptance test results.

Supervision based on reference to the former Ministry of Power Industry, Ministry of Machinery Industry issued by the electricity Office (1995) No. 37 "Interim Provisions for the quality supervision of large power equipment", "Regulations on the work of the general representative group in large power equipment manufacturers". Refer to DL/T 586-2008 Technical Guidelines for Equipment Supervision. GB/T 50319-2013 "Construction engineering supervision Code", GB/T 19000-2016/ISO 9000:2015 "Quality management and quality assurance" standard. The relevant commercial terms and technical agreements in the equipment purchase contract signed between the user and the manufacturer, including the documents, letters, correspondence and so on, which have legal effect. The product equipment drawing confirmed by the user and the manufacturer and the modification notice issued by the design unit. Technical documents and design drawings related to national standards, industry standards, enterprise standards (subject to the latest version). If the standards adopted by the technical documents and the design drawings are inconsistent with each other, the national standards, industry standards, and enterprise standards shall be adopted as the recurrence order. When the design drawing is inconsistent with the reference standard, the requirements in the standard shall prevail in principle, except for the special requirements of the parts.

Document witness, on-site witness and stoppage for inspection, namely R point, W point, H point. Each time after the completion of the supervision content, the supplier and the supervision representative will perform the signature procedure on the witness form. The supplier shall deliver one copy to the buyer's supervision representative. Point R: The supplier only needs to provide inspection or test records or reports of the item, that is, document witness. Point W: The inspection or test project attended by the representative of the buyer's supervision, that is, the on-site witness. H point: When the supplier stops to wait for the inspection or test of the buyer's supervision representative, that is, the project is stopped for inspection. Upon receipt of the witness notice, the buyer shall promptly send a representative to the site of the supplier's inspection or test to participate in on-site witness or stop work for inspection.

Sampling inspection items: DC resistance of cable conductor; Voltage test of finished cable; Conductor monofilament diameter and deviation; The average thickness and thinnest point of the insulator; The average thickness and thinnest point of the sheath; Outer diameter of cable; Ovality; Length marker, error.

Test item:Dc resistance of cable conductor; Voltage test of finished cable; Conductor monofilament diameter and deviation; The average thickness and thinnest point of the insulator; The average thickness and thinnest point of the sheath; Outer diameter of cable; Cable ovality; Length mark, error; Change rate of tensile strength and elongation of insulation and sheath before and after aging; Insulated wire core withstand voltage test; Thermal extension test; Ozone resistance test; Oil resistance test; Finished cable bending test, etc.

The purpose of the performance acceptance test is to check whether all the properties of the contract products meet the requirements.

The site of performance acceptance test shall be the buyer's site.

The performance acceptance test shall be carried out within 6 months after the 168-hour full load trial operation of the product, and the specific test time shall be determined by both parties through negotiation.

Installation of measuring points, primary components and local instruments required for performance acceptance test shall be provided by the supplier and cooperated by the buyer. The supplier shall also provide the technical cooperation and personnel cooperation required for the test.

The content of performance acceptance test shall be in accordance with the supplier's quality assurance and test requirements.

The standard of performance acceptance test shall be in accordance with the supplier's quality assurance and test requirements.

The performance acceptance test shall be conducted by the buyer and participated by the supplier. The test program shall be provided by the buyer and determined after discussion with the supplier. The specific test shall be completed by the testing department approved by both parties.

Confirmation of performance acceptance test results The performance acceptance test report shall be prepared by the testing unit, and the conclusions of the report shall be recognized by both parties. If there is any disagreement between the two parties on the results of the test, the two parties shall settle it through negotiation. If no agreement can be reached, it shall be submitted to the superior departments of both parties for negotiation.

When a performance acceptance test is conducted, if a party fails to send personnel to participate in the test after receiving the test notice from the other party, it shall be deemed to have agreed to the acceptance test results.

Supervision based on reference to the former Ministry of Power Industry, Ministry of Machinery Industry issued by the electricity Office (1995) No. 37 "Interim Provisions for the quality supervision of large power equipment", "Regulations on the work of the general representative group in large power equipment manufacturers". Refer to DL/T 586-2008 Technical Guidelines for Equipment Supervision. GB/T 50319-2013 "Construction engineering supervision Code", GB/T 19000-2016/ISO 9000:2015 "Quality management and quality assurance" standard. The relevant commercial terms and technical agreements in the equipment purchase contract signed between the user and the manufacturer, including the documents, letters, correspondence and so on, which have legal effect. The product equipment drawing confirmed by the user and the manufacturer and the modification notice issued by the design unit. Technical documents and design drawings related to national standards, industry standards, enterprise standards (subject to the latest version). If the standards adopted by the technical documents and the design drawings are inconsistent with each other, the national standards, industry standards, and enterprise standards shall be adopted as the recurrence order. When the design drawing is inconsistent with the reference standard, the requirements in the standard shall prevail in principle, except for the special requirements of the parts.

Document witness, on-site witness and stoppage for inspection, namely R point, W point, H point. Each time after the completion of the supervision content, the supplier and the supervision representative will perform the signature procedure on the witness form. The supplier shall deliver one copy to the buyer's supervision representative. Point R: The supplier only needs to provide inspection or test records or reports of the item, that is, document witness. Point W: The inspection or test project attended by the representative of the buyer's supervision, that is, the on-site witness. H point: When the supplier stops to wait for the inspection or test of the buyer's supervision representative, that is, the project is stopped for inspection. Upon receipt of the witness notice, the buyer shall promptly send a representative to the site of the supplier's inspection or test to participate in on-site witness or stop work for inspection.