| H07RNH6-F Cable | ||

| Voltage: | 300/500V | |

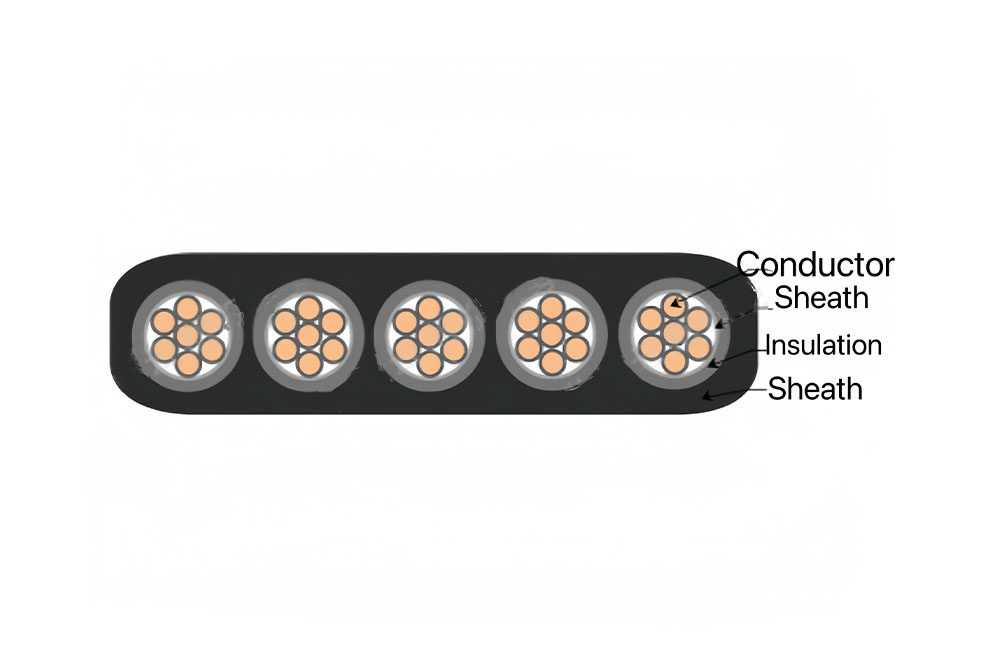

| Structure: | Conductor | Copper |

| Insulation | Rubber | |

| Jacket | Rubber | |

| Feature | Flexible cable | |

This cable is suitable for the power line with AC 50Hz and rated voltage is 300/500V.

It is used for outdoor medium-sized mobile electrical equipment and tools.

This cable has the characteristics of softness, and has certain weather resistance and certain oil resistance, it also can be used outdoors.

GB/T 8735-2011, the rubber insulated flexible wires and flexible cables with rated voltage of 450/750V and below.

The rated voltage is 0.3/0.5kV, and the maximum voltage of the AC system should not exceed 0.6kV.

The maximum allowable long-term operating temperature of the cable conductor is 60℃.

The minimum environment temperature which the cable can work properly is -10 ℃.

The laying temperature of the cable should not be lower than -10℃.

Recommended minimum bending radius: The bending radius of the cable should not exceed 10D.

GUOWANG CABLE GROUP

Color marking 2-core cable: no preference for chromatography; 3-core cable: green/yellow, light blue, brown or light blue, black, brown; 4-core cable: green/yellow, light blue, black, brown or light blue, black, brown, black or brown; 5-core cable: green/yellow, light blue, black, brown, black or brown, or light blue, black, brown, black or brown, black or brown.

The outer sheath of the cable is usually black, but a color other than black can also be used in accordance with the manufacturer or buyer's agreement to adapt to the environment. The cable shall have continuous identification of the manufacturer's name, product model and rated voltage, and the manufacturer's name identification may be repeated identification of the manufacturer or trademark; The distance between the end of one complete mark and the beginning of the next mark: it shall not exceed 550mm on the outer sheath of the cable; The cable insulation or belt should not exceed 275mm; The printed logo should be erasable and not easy to fall off, and the printed content on the surface should be clearly recognizable. Note: The logo on the surface of the sheath can also add other content according to the custom of the user or the manufacturer.

Each loop of cable should be 100m in length, and the length of the cable drum should be greater than 100m. Delivery of any length of cable may be permitted by mutual agreement.

Error In Length

The measurement error of delivery length is ±0.5%.

Cables in rolls and coils should be neatly wound and properly packed; The cable tray shall comply with the provisions of GB/T8137-1999; The cable ends should be securely sealed, and the cable ends extending out of the disk should be covered with a protective cover, the length of the cable ends extending out of the disk should be less than 300mm. It should be labeled with a content on the package of the cable: manufacturer name, model, specification, rated voltage, length, quality, manufacturing date, standard number or certification mark, the correct rotation direction of the cable tray, etc.

Transport is generally in the form of vehicles and ships, and the cable must be firmly fixed during transport to avoid bumping or tipping over to cause damage to the cable or drum. Do not lay the cable tray flat; It is strictly forbidden to drop the cable tray containing the cable from a height during transportation.

The finished cable should be stored in an environment where the temperature is between 5 and 35℃and the humidity is below 80%, so that it is not directly exposed to sunlight or rain, and should be properly ventilated to keep the environment dry.

The model, specification, length, delivery date, packing method and other necessary information of the cable should be correctly marked when ordering.

During installation, the operating temperature should not be lower than -10℃. If the ambient temperature measured by the thermometer is lower than 0℃, preheat the cable before preparing for installation. The bending radius of the multi-core cable should not exceed 10D (D is the outer diameter of the cable) to avoid mechanical damage inside the cable.

| SPECIFICATION | CONDUCTOR STRUCTURE | OUTER DIAMETER OF CONDUCTOR (MM) |

BELT (MM) |

INSULATION THICKNESS(MM) | SHEATH THICKNESS (MM) |

OUTSIDE DIAMETER (MM) |

WEIGHT (kg/km) |

MAXIMUM DC RESISTANCE AT 20℃ (Ω/km) | TESTING VOLATAGE (KV/min) | MAXIMUM ALLOWABLE TRACTIVE FORCE (N) |

| 2×0.75 | 24/0.20 | 1.12 | 8×0.05 | 0.6 | 0.8 | 4.1×6.6 | 45.5 | 26 | 2/5 | 105 |

| 2×1.0 | 32/0.20 | 1.29 | 5×0.05 /8×0.05 |

0.6 | 0.9 | 4.4×7.0 | 54.8 | 19.5 | 2/5 | 140 |

| 2×1.5 | 30/0.25 | 1.56 | 8×0.05 | 0.8 | 1 | 5.4×8.6 | 80.5 | 13.3 | 2/5 | 210 |

| 2×2.5 | 49/0.25 | 2 | 8×0.05 | 0.9 | 1.1 | 6.2×10.2 | 116 | 7.98 | 2/5 | 350 |

| 2×4 | 56/0.30 | 2.56 | 8×0.05 | 1.0 | 1.2 | 7.1×11.8 | 166.3 | 4.95 | 2/5 | 560 |

| 2×6 | 84/0.30 | 3.54 | 10×0.05 | 1.0 | 1.3 | 8.2×13.8 | 225.4 | 3.3 | 2/5 | 840 |

| 3×0.75 | 24/0.20 | 1.12 | 8×0.05 | 0.6 | 0.9 | 4.3×6.8 | 60.2 | 26 | 2/5 | 158 |

| 3×1.0 | 32/0.20 | 1.29 | 8×0.05 | 0.6 | 0.9 | 4.4×7.0 | 69.4 | 19.5 | 2/5 | 210 |

| 3×1.5 | 30/0.25 | 1.56 | 8×0.05 | 0.8 | 1.0 | 5.3×8.6 | 102.8 | 13.3 | 2/5 | 315 |

| 3×2.5 | 49/0.25 | 2 | 8×0.05 | 0.9 | 1.1 | 6.2×10.2 | 150.1 | 7.98 | 2/5 | 525 |

| 3×4 | 56/0.30 | 2.56 | 8×0.05 | 1.0 | 1.2 | 7.1×11.8 | 218.8 | 4.95 | 2/5 | 840 |

| 3×6 | 84/0.30 | 3.54 | 10×0.05 | 1.0 | 1.3 | 8.2×13.8 | 298.4 | 3.3 | 2/5 | 1260 |

| 4×0.75 | 24/0.20 | 1.12 | 8×0.05 | 0.6 | 0.9 | 4.3×6.8 | 72.0 | 26 | 2/5 | 210 |

| 4×1.0 | 32/0.20 | 1.29 | 8×0.05 | 0.6 | 0.9 | 4.4×7.0 | 84.0 | 19.5 | 2/5 | 280 |

| 4×1.5 | 30/0.25 | 1.56 | 5×0.05 | 0.8 | 1.0 | 5.8×9.3 | 137.4 | 13.3 | 2/5 | 420 |

| 4×2.5 | 49/0.25 | 2 | 5×0.05 | 0.9 | 1.1 | 6.6×10.7 | 198.0 | 7.98 | 2/5 | 700 |

| 4×4 | 56/0.30 | 2.56 | 5×0.05 | 1.0 | 1.2 | 7.6×12.5 | 290.1 | 4.95 | 2/5 | 1120 |

| 4×6 | 84/0.30 | 3.54 | 10×0.05 | 1.0 | 1.3 | 9.2×15.5 | 411.8 | 3.3 | 2/5 | 1680 |

| 5×0.75 | 24/0.20 | 1.12 | 5×0.05 | 0.6 | 1.0 | 4.7×7.3 | 92.3 | 26 | 2/5 | 263 |

| 5×1.0 | 32/0.20 | 1.29 | 5×0.05 | 0.6 | 1.0 | 4.9×7.7 | 108.5 | 19.5 | 2/5 | 350 |

| 5×1.5 | 30/0.25 | 1.56 | 5×0.05 | 0.8 | 1.1 | 5.8×9.3 | 160.8 | 13.3 | 2/5 | 525 |

| 5×2.5 | 49/0.25 | 2 | 5×0.05 | 0.9 | 1.3 | 6.8×10.9 | 238.3 | 7.98 | 2/5 | 875 |

| 5×4 | 56/0.30 | 2.56 | 5×0.05 | 1.0 | 1.4 | 7.8×12.7 | 350.1 | 4.95 | 2/5 | 1400 |

| 5×6 | 84/0.30 | 3.54 | 10×0.05 | 1.0 | 1.6 | 9.7×16.0 | 506.8 | 3.3 | 2/5 | 2100 |

| 6×0.75 | 24/0.20 | 1.12 | 5×0.05 | 0.6 | 1.0 | 4.7×7.3 | 104.7 | 26 | 2/5 | 315 |

| 6×1.0 | 32/0.20 | 1.29 | 5×0.05 | 0.6 | 1.1 | 5.1×7.9 | 127.2 | 19.5 | 2/5 | 420 |

| 6×1.5 | 30/0.25 | 1.56 | 5×0.05 | 0.8 | 1.2 | 6.0×9.5 | 188.2 | 13.3 | 2/5 | 630 |

| 6×2.5 | 49/0.25 | 2 | 5×0.05 | 0.9 | 1.4 | 7.0×11.1 | 278.7 | 7.98 | 2/5 | 1050 |

| 6×4 | 56/0.30 | 2.56 | 5×0.05 | 1.0 | 1.5 | 8.1×13.0 | 413.0 | 4.95 | 2/5 | 1680 |

| 6×6 | 84/0.30 | 3.54 | 10×0.05 | 1.0 | 1.7 | 9.9×16.2 | 591.9 | 3.3 | 2/5 | 2520 |

We are based in Henan, China, start from 2012,sell to Domestic Market(70.00%), Mid East(11.00%), South America(10.00%), Africa(3.00%), North America(2.00%), Southeast Asia(2.00%), Eastern Asia(00.00%), South Asia(00.00%). There are total about 101-200 people in our office.

Always a pre-production sample before mass production; Always final Inspection before shipment.

Wire, Cable

We have twenty years of experience in design and development

Accepted Delivery Terms: FOB,CFR,CIF,EXW;

Accepted Payment Currency: USD,EUR;

Accepted Payment Type: T/T,L/C,Money Gram,Western Union;

Language Spoken: English,Chinese,French

Most quotes are returned within 24 hours

Sampling inspection items: DC resistance of cable conductor; Voltage test of finished cable; Conductor monofilament diameter and deviation; The average thickness and thinnest point of the insulator; The average thickness and thinnest point of the sheath; Outer diameter of cable; Ovality; Length marker, error.

Test item:Dc resistance of cable conductor; Voltage test of finished cable; Conductor monofilament diameter and deviation; The average thickness and thinnest point of the insulator; The average thickness and thinnest point of the sheath; Outer diameter of cable; Cable ovality; Length mark, error; Change rate of tensile strength and elongation of insulation and sheath before and after aging; Insulated wire core withstand voltage test; Thermal extension test; Ozone resistance test; Finished cable bending test, etc.

The purpose of the performance acceptance test is to check whether all the properties of the contract products meet the requirements.

The site of performance acceptance test shall be the buyer's site.

The performance acceptance test shall be carried out within 6 months after the 168-hour full load trial operation of the product, and the specific test time shall be determined by both parties through negotiation.

Installation of measuring points, primary components and local instruments required for performance acceptance test shall be provided by the supplier and cooperated by the buyer. The supplier shall also provide the technical cooperation and personnel cooperation required for the test.

The content of performance acceptance test shall be in accordance with the supplier's quality assurance and test requirements.

The standard of performance acceptance test shall be in accordance with the supplier's quality assurance and test requirements.

The performance acceptance test shall be conducted by the buyer and participated by the supplier. The test program shall be provided by the buyer and determined after discussion with the supplier. The specific test shall be completed by the testing department approved by both parties.

Confirmation of performance acceptance test results The performance acceptance test report shall be prepared by the testing unit, and the conclusions of the report shall be recognized by both parties. If there is any disagreement between the two parties on the results of the test, the two parties shall settle it through negotiation. If no agreement can be reached, it shall be submitted to the superior departments of both parties for negotiation.

When a performance acceptance test is conducted, if a party fails to send personnel to participate in the test after receiving the test notice from the other party, it shall be deemed to have agreed to the acceptance test results.

Supervision based on reference to the former Ministry of Power Industry, Ministry of Machinery Industry issued by the electricity Office (1995) No. 37 "Interim Provisions for the quality supervision of large power equipment", "Regulations on the work of the general representative group in large power equipment manufacturers". Refer to DL/T 586-2008 Technical Guidelines for Equipment Supervision. GB/T 50319-2013 "Construction engineering supervision Code", GB/T 19000-2016/ISO 9000:2015 "Quality management and quality assurance" standard. The relevant commercial terms and technical agreements in the equipment purchase contract signed between the user and the manufacturer, including the documents, letters, correspondence and so on, which have legal effect. The product equipment drawing confirmed by the user and the manufacturer and the modification notice issued by the design unit. Technical documents and design drawings related to national standards, industry standards, enterprise standards (subject to the latest version). If the standards adopted by the technical documents and the design drawings are inconsistent with each other, the national standards, industry standards, and enterprise standards shall be adopted as the recurrence order. When the design drawing is inconsistent with the reference standard, the requirements in the standard shall prevail in principle, except for the special requirements of the parts.

Document witness, on-site witness and stoppage for inspection, namely R point, W point, H point. Each time after the completion of the supervision content, the supplier and the supervision representative will perform the signature procedure on the witness form. The supplier shall deliver one copy to the buyer's supervision representative. Point R: The supplier only needs to provide inspection or test records or reports of the item, that is, document witness. Point W: The inspection or test project attended by the representative of the buyer's supervision, that is, the on-site witness. H point: When the supplier stops to wait for the inspection or test of the buyer's supervision representative, that is, the project is stopped for inspection. Upon receipt of the witness notice, the buyer shall promptly send a representative to the site of the supplier's inspection or test to participate in on-site witness or stop work for inspection.